Zortrax Inkspire 2 Resin 3D Printer with Cleaning and Curing Station Bundle Zortrax

$ 10.995,90 $ 2.748,97

Bundle Includes:

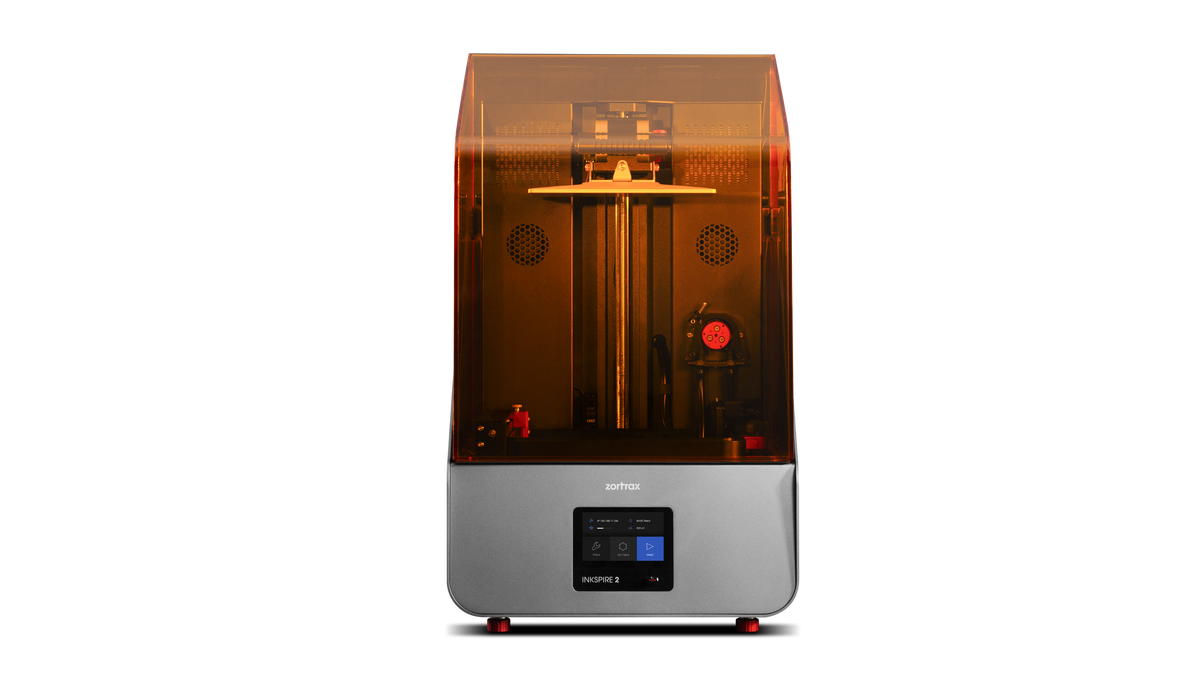

1 x Zortrax Inkspire 2 3D Printer

1 x Zortrax Curing Station

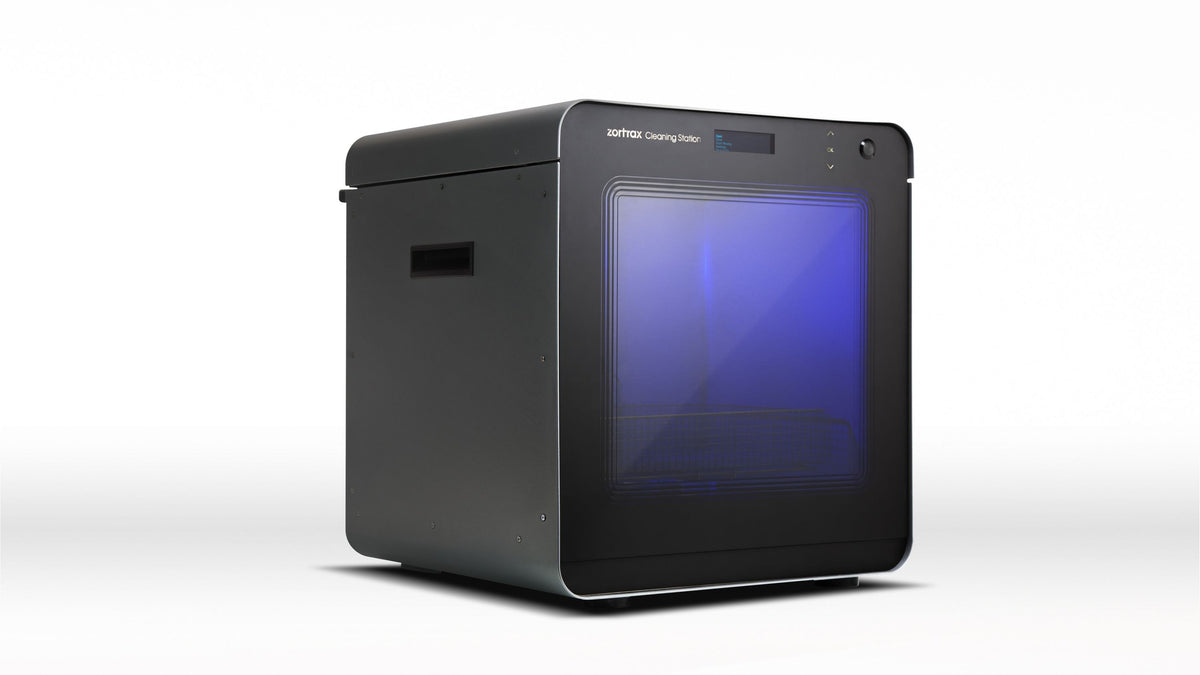

1 x Zortrax Cleaning Station

Light Engine

UV LED light source 405nm. proprietary matrix of light LEDs and light distribution guarantees uniform UV exposure across the entire build platform and high optical precision of every single pixel regardless of how much of the build platform is filled. In consequence, the same high dimensional accuracy can be achieved both in the center and on the edges of the build platform. Due to this proprietary technology, the Inkspire 2 guarantees the highest mechanical and thermal properties of prints made with professional resins from world-leading manufacturers like BASF or Henkel.

UV Cover

The UV cover effectively protects against exposure of resins to external UV light sources and reduces the emission of vapors to the environment.

Build Platform Removal Mechanism and Resin Dripping

The build platform can be removed and attached back in the same exact position. The mounting enables leaving the build platform in an angled position which facilities resin dripping after the printing is done.

Calibration

The build platform is factory-calibrated which means the Inkspire 2 is ready for work out of the box. If necessary, the printer can be also calibrated by the user following a GUI’s simple manual. The calibration process is based on the adjustment of 3 platform screws.

Resin Vat

Fitted with an easy removal and attachments system making positioning easier along with a system improving the FEP membrane functioning.

Resin Level Control System Components:

- Resin pump. Due to the automatic resin feeding system the Inskpire 2 can transfer more of the resin directly from the bottle if the amount present in the vat is not enough to get the print done. Resin bottles can be easily attached to the pump and placed in a dedicated holder.

- The pump works both ways. There is no need to remove the resin vat to transfer excessive resin back to the bottle. The pump can do it automatically.

- Resin wiper mechanism keeping the optimal dispersion in the resin. The wiper working in the vat prevents sedimentation in the resin which often occurs in more complex photopolymers during longer prints. The wiper speed is adjusted for each resin calibrated for the Inkspire 2.

- Resin level sensor. Placed in the resin vat, the sensor constantly measures how much resin is left. Keeping the resin level steady, to an extent, solves the issue of oxygen inhibition which keeps the photopolymers from solidifying.

- Resin bottle mass sensor. The sensor complements the sensor placed in the resin vat and measures how much resin is left in the bottle placed in the holder. Readouts from both sensors asses how much resin is overall available for the current print. The bottle holder is designed to accommodate most popular resin bottle designs.

If the Inkspire 2 detects that there is not enough resin to finish the print, it notifies the user with appropriate message on the screen. If the resin runs out during printing, the process will be paused automatically.

Safety

Thanks to the updated safety features for the Inkspire 2 the print will automatically be paused when a power outage is detected and resume from the same spot when the power is back on. The printer also has resin level control systems as well as built-in Carbon and Hepa filters to limit the user’s exposure to resin fumes.

Other

Device rinsing and cleaning functions adjustable in firmware, adjustable feet to enable easy leveling of the printer on the surface.

Fast Delivery and professional packaging

Our long-standing relationships with UPS FedEx DHL and other international carriers lets us offer various shipping options. Our warehouse personnel are well trained and will be able to pack the goods according to the exact and precise specifications. The goods you send us are checked thoroughly and securely secured prior to shipment. Everyday we deliver thousands of packages to customers across many countries. The fact that we're committed to becoming the biggest online retailer in the World is clear. The warehouses and centers of distribution are in Europe and the USA.

It is important to note that orders with more than one item will be subject to a processing period that is based to the specific item.

Prior to shipping Our team will conduct an extensive inspection of the items you purchased. The majority of orders today are shipped in 48 hours. The delivery time is between 3-7 days.

Returns

Due to multiple entities which include the factory as well as the warehouse, we're unable to completely manage our stock. Stock levels can fluctuate at any given time. It is possible that inventory could run out once your order has been processed.

Our policy is valid for 30 days. We are unable to return or exchange your purchase when it's been 30 days since you purchased it.

The item you purchase must be in its original packaging and be unused. The item must be in its original packaging.

Related products

3D Printer Parts & Spares

3D Printer Parts & Spares

3D Printer Parts & Spares

3D Printer Parts & Spares

3D Printers

3D Printers

3D scanners

3D Printer Parts & Spares

3D scanners

3D Printer Parts & Spares

3D Printer Parts & Spares

3D Printer Parts & Spares

3D Printer Parts & Spares

3D Printer Parts & Spares

3D Printers

3D Printers

3D Printer Parts & Spares

7ml Super Lube Multi-Use Synthetic Oil with Syncolon (PTFE) SuperLube

3D Printer Parts & Spares

3D Printers

3D Printers

3D Printer Parts & Spares

3D Printer Parts & Spares

3D Printers

3D Printers

3D Printer Parts & Spares

3D Printers