Zortrax Endureal 3D Printer Zortrax

$ 0,00

High-temp polymers processing

Zortrax Endureal is an industrial machine designed for processing of high-temperature polymers* like Z-PEEK, Z-PEI 1010, Z-PEI 9085. Such materials require very high extrusion temperatures but offer excellent mechanical properties comparable to metal alloys. Z-PEI 9085 is an aerospace-grade polymer used to build flame-retardant elements of aircraft interiors. It is one of the few 3D printing materials cleared for use onboard the International Space Station. Z-PEI 9085 can be printed with breakaway support structures in dual extrusion mode.

Three thermal zones

Operating at very high temperatures, the Endureal has three thermally shielded zones. Due to this thermal shielding, the extruder and filament cables are kept in an environment not exceeding 50° C even when the chamber right beneath them is heated up to 200° C. The third thermal zone is the filament chamber where filaments are stored at optimal temperature and humidity.

High user-serviceability

Zortrax Endureal has been designed to be highly user-serviceable. All key components like the extruder, hotend or nozzles can be quickly replaced in-house without voiding the warranty. A maintenance kit that comes with the printer contains all necessary parts and consumables to ensure uninterrupted operation. There is no need to wait for qualified service personnel to intervene in most cases.

Advanced thermal management

Temperatures at each thermal processing stage a polymer has to go through in the Zortrax Endureal can significantly affect the mechanical properties of the printed model. That’s why the temperatures at three crucial points i.e. at the extrusion, and the build platform and in the printing chamber can be precisely defined by the user. This way, the Endureal can be quickly fine-tuned to work with most high-temp polymers on the market as well as experimental or custom-made materials available in small amounts.

Fast Delivery and professional packaging

Our long-standing relationships with UPS FedEx DHL and other international carriers lets us offer various shipping options. Our warehouse personnel are well trained and will be able to pack the goods according to the exact and precise specifications. The goods you send us are checked thoroughly and securely secured prior to shipment. Everyday we deliver thousands of packages to customers across many countries. The fact that we're committed to becoming the biggest online retailer in the World is clear. The warehouses and centers of distribution are in Europe and the USA.

It is important to note that orders with more than one item will be subject to a processing period that is based to the specific item.

Prior to shipping Our team will conduct an extensive inspection of the items you purchased. The majority of orders today are shipped in 48 hours. The delivery time is between 3-7 days.

Returns

Due to multiple entities which include the factory as well as the warehouse, we're unable to completely manage our stock. Stock levels can fluctuate at any given time. It is possible that inventory could run out once your order has been processed.

Our policy is valid for 30 days. We are unable to return or exchange your purchase when it's been 30 days since you purchased it.

The item you purchase must be in its original packaging and be unused. The item must be in its original packaging.

Related products

3D Printer Parts & Spares

12g Super Lube Multi-Purpose Synthetic Grease with Syncolon (PTFE) SuperLube

3D Printer Parts & Spares

3D Printer Parts & Spares

3D Printer Parts & Spares

3D Printer Parts & Spares

3D Printer Parts & Spares

7ml Super Lube Multi-Use Synthetic Oil with Syncolon (PTFE) SuperLube

3D scanners

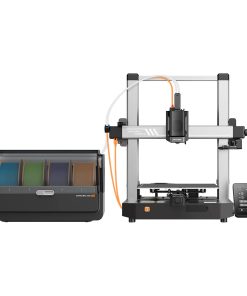

3D Printers

3D scanners

3D Printers

3D Printers

3D Printer Parts & Spares

3D scanners

3D Printers

3D Printer Parts & Spares

85g Super Lube Multi-Purpose Synthetic Grease with Syncolon (PTFE) SuperLube

3D Printer Parts & Spares

3D Printer Parts & Spares

3D Printers

3D Printer Parts & Spares

3D Printers

3D Printers

3D Printers

3D Printer Parts & Spares

3D scanners

3D Printers

3D Printer Parts & Spares