xTool P2 55W CO2 Desktop Laser Cutter xTool

$ 4.399,00 $ 1.099,75

Smarter Than Ever Before

After nearly 2 years of development, xTool P2 comes out with many new features that showcase an impressive level of innovation and intelligence, bringing users a cutting-edge experience.

Intelligent Features:

- Automatic passthrough: precision and convenience

- Curved surface engraving: automatically construct 3D models

- Batch engraving: recognize shapes

Dual 16MP

With high-accuracy live preview and auto-focus features, you can easily drag your drawings to the right place you want. Everyone can master xTool P2 in minutes.

Panoramic Camera

Panoramic camera provides a live preview and facilitates easy positioning by taking a whole picture of the working space in three seconds. What you see is what you get.

Strong Performance

xTool P2 has a powerful 55W laser tube that makes it achievable to cut 18mm black walnut and 20mm acrylic in one pass. CO2 laser has ultra-high absorption efficiency on wood and acrylic. P2 can cut 3mm basswood at the speed of 35mm/s , which is 6 times faster than a 20W diode laser.

Boundless Creativity

xTool P2 provides a large bed size, the dimension is 26″×14″ (680*360mm). The processing area is 23.6”×12.1” (600*308mm).

It only takes a few accessories to get a more versatile P2 and unlimited possibilities. The machine itself supports processing on objects up to 71mm thick. Risers: With the riser base, it can be up to the thickest of 215mm. So users can easily customize their suitcase. Rotary Engraving: Compatible with RA2 Pro, the 4-in-1 rotary attachment. xTool P2 unleashes your creativity on tumblers, mugs, spheres and rings.

Safety Features:

- Enclosed Design

- Emergency Stop Button

- Fire Safety

- Automatic Lock

- Hydraulic Support

- Multiple-Warning System

Other Functions

- Built-in air assist: The built-in air assist will effectively blow away smoke and dust, allowing users to get better cutting and engraving results, while keeping the laser head clean.

- Professional knife strip base plate: The industrial level of the knife strip base plate reduces the impact of burning and fuming on the bottom of the material. Compared with honeycomb board, it is easier to clean the machine, helping get more space for fume extraction and better results on the bottom of carved works.

- Built-in exhaust fan: With a built-in adjustable air assist and slats, the smoke can easily get through the materials and ventilated by the 145CFM exhaust fan.

- More stable laser tube protection: Instead of moving with the Y-beam, fixing the laser tube at the back of the machine will make the laser tube more stable; adding more pearl cotton will also protect the laser tube transportation safely.

Fast Delivery and professional packaging

Our long-standing relationships with UPS FedEx DHL and other international carriers lets us offer various shipping options. Our warehouse personnel are well trained and will be able to pack the goods according to the exact and precise specifications. The goods you send us are checked thoroughly and securely secured prior to shipment. Everyday we deliver thousands of packages to customers across many countries. The fact that we're committed to becoming the biggest online retailer in the World is clear. The warehouses and centers of distribution are in Europe and the USA.

It is important to note that orders with more than one item will be subject to a processing period that is based to the specific item.

Prior to shipping Our team will conduct an extensive inspection of the items you purchased. The majority of orders today are shipped in 48 hours. The delivery time is between 3-7 days.

Returns

Due to multiple entities which include the factory as well as the warehouse, we're unable to completely manage our stock. Stock levels can fluctuate at any given time. It is possible that inventory could run out once your order has been processed.

Our policy is valid for 30 days. We are unable to return or exchange your purchase when it's been 30 days since you purchased it.

The item you purchase must be in its original packaging and be unused. The item must be in its original packaging.

Related products

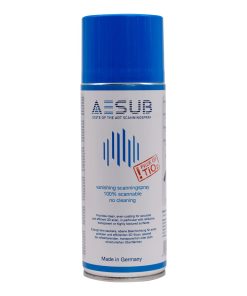

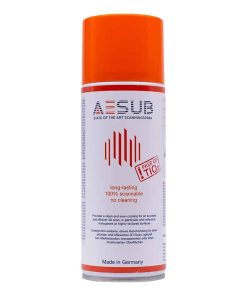

3D scanners

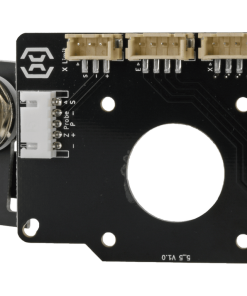

3D Printer Parts & Spares

7ml Super Lube Multi-Use Synthetic Oil with Syncolon (PTFE) SuperLube

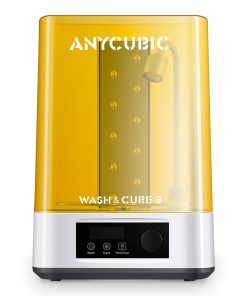

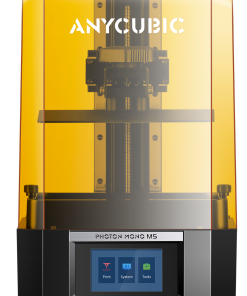

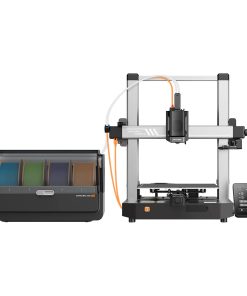

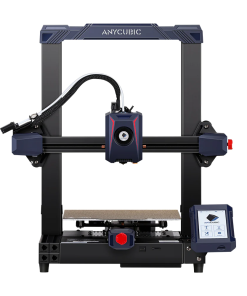

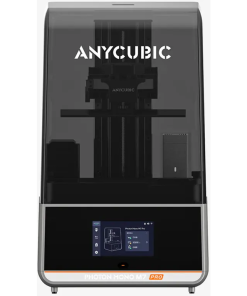

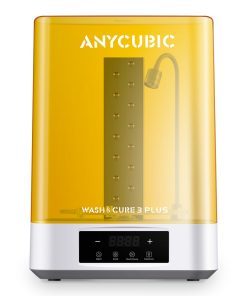

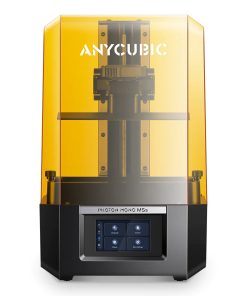

3D Printers

3D scanners

3D Printer Parts & Spares

3D Printer Parts & Spares

85g Super Lube Multi-Purpose Synthetic Grease with Syncolon (PTFE) SuperLube

3D Printer Parts & Spares

3D Printers

3D Printers

3D Printer Parts & Spares

3D Printers

3D scanners

3D Printers

3D Printers

3D Printer Parts & Spares

3D Printer Parts & Spares

3D Printer Parts & Spares

3D Printers

3D Printer Parts & Spares

3D Printers

3D Printer Parts & Spares

3D Printers

3D Printers