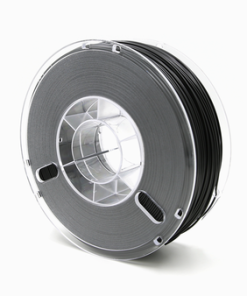

RAISE3D R3D PREMIUM ABS FILAMENT 1.0KG 1.75MM Raise3D

$ 35,99 $ 21,59

Raise3D Premium ABS

ABS (Acrylonitrile butadiene styrene) is a thermoplastic 3D printing filament characterized by its reliability, stiffness, strength, and impact resistance. It also features higher dimensional stability and chemical resistance. These features make it useful for engineering, prototyping, function testing, part assembling and a lot more. ABS 3D printed parts are used in electronics cases, toys, and automotive body parts, just to name a few. Raise3D’s Premium ABS filament is both ISO 9001 and ISO 14001 certified.

Features

ABS or Acrylonitrile Butadiene Styrene is one of the most widely used industrial thermoplastics, which has great mechanical properties and good heat resistance up to 90°C. Parts printed with ABS are not only widely used in the prototyping stage of product development, but also in later stage of function testing and parts assembling. Printed ABS parts have been successfully used in the manufacturing application with or without post-finishing. To print ABS successfully, heated bed and closed chamber is necessary; to print ABS in office/factory and indoor environments, an air filter is recommended.

Applications

Functional prototyping

Applications

- Tools and fitting

- Prototyping and concept models

Material Performance

Printing Notifications:

- For a better bed adhesion, brim or raft are recommended and set bed temperature at 100 °C and turn off the cooling fan for the first few layers.

- PLA can be used for break-away support material for ABS.

For ideaMaker Users:

Choose the right printing profile for ABS on ideaMaker IO and use it on ideaMaker. Download the latest version of ideaMaker.

| Colour | Black, White |

|---|

Fast Delivery and professional packaging

Our long-standing relationships with UPS FedEx DHL and other international carriers lets us offer various shipping options. Our warehouse personnel are well trained and will be able to pack the goods according to the exact and precise specifications. The goods you send us are checked thoroughly and securely secured prior to shipment. Everyday we deliver thousands of packages to customers across many countries. The fact that we're committed to becoming the biggest online retailer in the World is clear. The warehouses and centers of distribution are in Europe and the USA.

It is important to note that orders with more than one item will be subject to a processing period that is based to the specific item.

Prior to shipping Our team will conduct an extensive inspection of the items you purchased. The majority of orders today are shipped in 48 hours. The delivery time is between 3-7 days.

Returns

Due to multiple entities which include the factory as well as the warehouse, we're unable to completely manage our stock. Stock levels can fluctuate at any given time. It is possible that inventory could run out once your order has been processed.

Our policy is valid for 30 days. We are unable to return or exchange your purchase when it's been 30 days since you purchased it.

The item you purchase must be in its original packaging and be unused. The item must be in its original packaging.

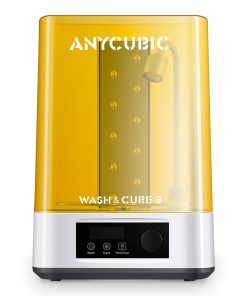

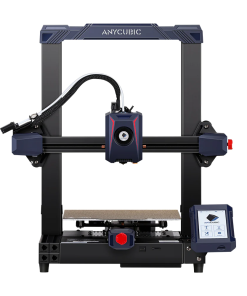

Related products

3D Printers

3D Printers

3D Printer Parts & Spares

3D Printer Parts & Spares

3D Printer Parts & Spares

3D Printers

3D Printer Parts & Spares

3D Printer Parts & Spares

12g Super Lube Multi-Purpose Synthetic Grease with Syncolon (PTFE) SuperLube

3D Printer Parts & Spares

3D Printers

3D Printers

3D Printer Parts & Spares

3D Printer Parts & Spares

3D Printer Parts & Spares

3D Printer Parts & Spares

85g Super Lube Multi-Purpose Synthetic Grease with Syncolon (PTFE) SuperLube

3D Printer Parts & Spares

3D Printer Parts & Spares

3D Printer Parts & Spares

3D Printers

3D Printers

3D Printers

3D Printers

3D Printer Parts & Spares

3D Printers

3D Printer Parts & Spares

3D Printers

3D Printer Parts & Spares

7ml Super Lube Multi-Use Synthetic Oil with Syncolon (PTFE) SuperLube