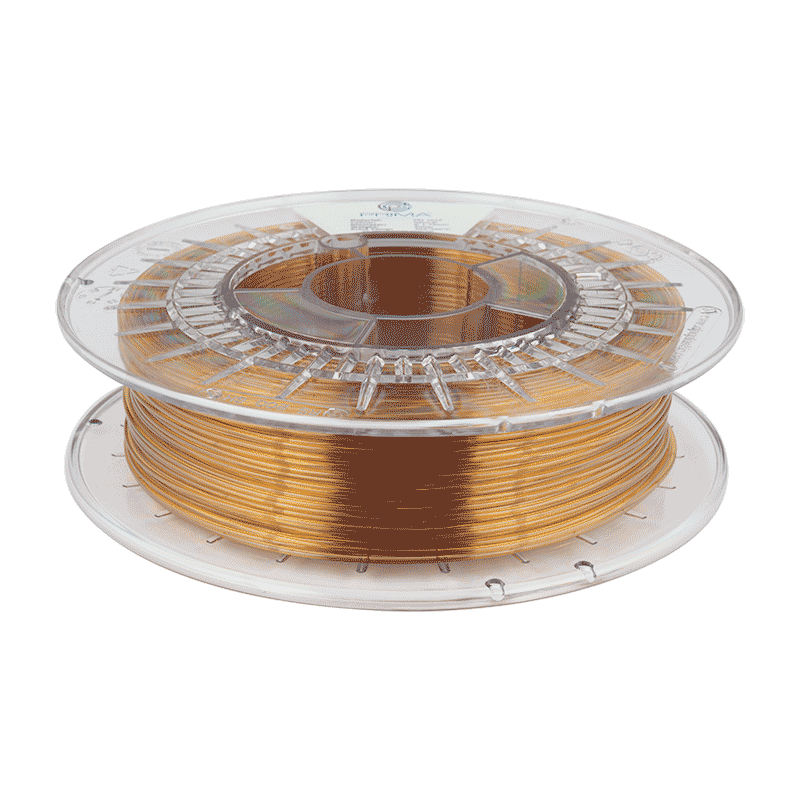

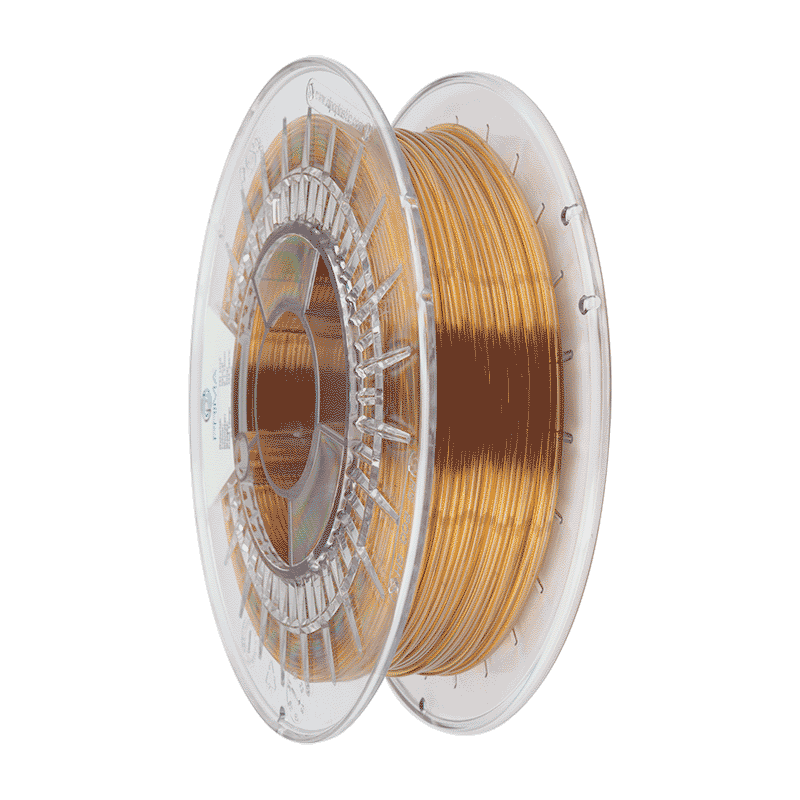

PrimaSelect PEI Ultem 1010 – 1.75mm – 500g – Natural PrimaCreator

$ 149,90 $ 59,96

Polyether Imide (PEI) Ultem 1010 is an amorphous, amber to transparent thermoplastics with a glass transition temperature (Tg) of 217 °C and performs in continuous use up to 170 °C. This inherently flame retardant plastic has UL94 V0 and 5VA ratings.

The PrimaCreator PEI Filament has unique properties because it does not come into contact with water during the production process and is directly packaged in a vacuum packaging. These properties make the PrimaCreator PEI Filament particularly suitable for usage in FDM and FFF 3D printers. The material has an excellent adhesion between layers which results in great improvement of the impact resistance, strength, durability and the printing process.

To make a successful PEI print there are a few things to keep in mind.

The printer must have the performance to meet the PEI filament and it should be printed with a nozzle temperature of 350-380°C. The heat bed should be set to 120-160°C and a heated chamber is important to have. It´s also very important to make sure that the printer is placed in a room where there´s hardly any draft and temperature fluctuations.

PEEK is best printed on a PEI sheet at a printing speed of 15-30 mm/s.

ESSENTIAL DATA:

| Material |

Polyether Imide |

| Diameter | 1.75mm |

| Tolerance | ± 0.05 mm |

| Heated build platform required | Yes, 120-160° C |

| Print Temperature | 355 – 390° C |

| Recommended Print Speed | 15-30 mm/s |

| Weight Filament | 500 grams |

TECHNICAL DATA:

| Property | Test method | Value |

| Density | ISO 1183 | 1,27 g/cm3 |

| Tensile Modulus | ISO 527 | 3200 MPa |

| Tensile Strength | ISO 527 | 105 MPa |

| Impact strength | ISO 180 | 5 KJ/m2 |

Fast Delivery and professional packaging

Our long-standing relationships with UPS FedEx DHL and other international carriers lets us offer various shipping options. Our warehouse personnel are well trained and will be able to pack the goods according to the exact and precise specifications. The goods you send us are checked thoroughly and securely secured prior to shipment. Everyday we deliver thousands of packages to customers across many countries. The fact that we're committed to becoming the biggest online retailer in the World is clear. The warehouses and centers of distribution are in Europe and the USA.

It is important to note that orders with more than one item will be subject to a processing period that is based to the specific item.

Prior to shipping Our team will conduct an extensive inspection of the items you purchased. The majority of orders today are shipped in 48 hours. The delivery time is between 3-7 days.

Returns

Due to multiple entities which include the factory as well as the warehouse, we're unable to completely manage our stock. Stock levels can fluctuate at any given time. It is possible that inventory could run out once your order has been processed.

Our policy is valid for 30 days. We are unable to return or exchange your purchase when it's been 30 days since you purchased it.

The item you purchase must be in its original packaging and be unused. The item must be in its original packaging.

Related products

3D Printer Parts & Spares

Bambu Lab Hardened Steel Hotend for A1 Series 0.8mm Bambu Lab

3D Printers

3D Printers

3D Printer Parts & Spares

3D Printers

3D Printers

3D Printers

3D Printer Parts & Spares

3D Printers

3D scanners

3D scanners

3D Printer Parts & Spares

Bambu Lab Hardened Steel Hotend for A1 Series 0.6mm Bambu Lab

3D Printer Parts & Spares

Bambu Lab Hardened Steel Hotend for A1 Series 0.4mm Bambu Lab

3D Printer Parts & Spares

85g Super Lube Multi-Purpose Synthetic Grease with Syncolon (PTFE) SuperLube

3D Printer Parts & Spares

Bambu Lab Complete Hotend Assembly for P1 Series Hardened Steel 0.4mm Bambu Lab

3D Printer Parts & Spares

Bambu Lab Complete Hotend Assembly for P1 Series Stainless Steel 0.2mm Bambu Lab

3D scanners

3D Printers

3D Printer Parts & Spares

3D Printers

3D Printer Parts & Spares

3D Printer Parts & Spares

3D Printers

3D Printer Parts & Spares

3D Printer Parts & Spares