PrimaSelect™ FLEX Filament – 1.75mm – 500g PrimaCreator

$ 14,95 $ 8,97

PrimaSELECT Flex is a new type of Thermoplastic Co-Polyester (TPC) with very rubber – like characteristics. This material is perfect when you need a strong, but still flexible filament. Our filament has a shore hardness of 45, which means that it´s rigid but still pliable.

PrimaSELECT Flex can create object that are stretchable and can survive punishment that no ABS or PLA could tolerate. Another great thing with PrimaSELECT Flex is it´s great UV and chemical resistance. The material can be bend and stretched but will always go back to its original shape. The one application that most people know this material from is mobile phone cases, so it´s great for usage where you need the material to fit the model, not the other way around.

PrimaSELECT Flex is best used with a heated bed which should be set to 90 – 100˚C it could also be used without heated bed depending on the type and size of your print.

A print speed of 10-30 mm/sec are to prefer due to the materials flexibility.

PrimaSELECT Flex sticks on BuildTak or glass plate coated with adhesive spray or glue stick.

PrimaSELECT Flex is reeled on a transparent spool with 500 g of high quality filament. It´s packed in a sturdy box and packed with silica gel to avoid moister.

PrimaSELECT Flex are available in diameter sizes of 1.75 mm and 2.85 mm.

Our state of the art factory is equipped with the latest in laser measuring technology to ensure that you will receive a spool of filament with a very tight diameter and roundness tolerance. This in turn makes for a filament that is compatible with most common printers on the market today.

Why should I choose PrimaSELECT Flex?

- High flexibility with a shore hardness of 45D

- Good resistance to chemicals

- High UV resistance

- Good heat resistance

| Colour | Black, White, Red, Blue |

|---|

Fast Delivery and professional packaging

Our long-standing relationships with UPS FedEx DHL and other international carriers lets us offer various shipping options. Our warehouse personnel are well trained and will be able to pack the goods according to the exact and precise specifications. The goods you send us are checked thoroughly and securely secured prior to shipment. Everyday we deliver thousands of packages to customers across many countries. The fact that we're committed to becoming the biggest online retailer in the World is clear. The warehouses and centers of distribution are in Europe and the USA.

It is important to note that orders with more than one item will be subject to a processing period that is based to the specific item.

Prior to shipping Our team will conduct an extensive inspection of the items you purchased. The majority of orders today are shipped in 48 hours. The delivery time is between 3-7 days.

Returns

Due to multiple entities which include the factory as well as the warehouse, we're unable to completely manage our stock. Stock levels can fluctuate at any given time. It is possible that inventory could run out once your order has been processed.

Our policy is valid for 30 days. We are unable to return or exchange your purchase when it's been 30 days since you purchased it.

The item you purchase must be in its original packaging and be unused. The item must be in its original packaging.

Related products

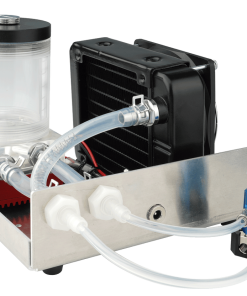

3D Printer Parts & Spares

Paints & Accessories

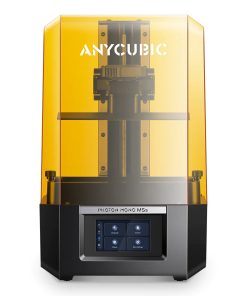

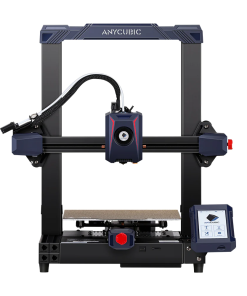

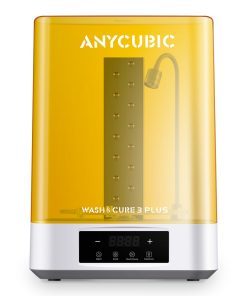

3D Printers

3D Printer Parts & Spares

3D Printers

Bed Adhesive

3D Printer Parts & Spares

Bed Adhesive

3D Printers

Bed Adhesive

3D Printers

Paints & Accessories

3D Printer Parts & Spares

3D Printers

3D Printers

3D Printer Parts & Spares

3D Printers

Bed Adhesive

3D Printer Parts & Spares

Paints & Accessories

3D Printers

3D Printer Parts & Spares

85g Super Lube Multi-Purpose Synthetic Grease with Syncolon (PTFE) SuperLube

Bed Adhesive

3D Printer Parts & Spares

12g Super Lube Multi-Purpose Synthetic Grease with Syncolon (PTFE) SuperLube

Bed Adhesive