Monocure 3D Rapid Resin – 0.5LTR MonoCure

$ 15,90 $ 9,54

Monocure Rapid 3D Resin – High quality good-value resin for your UV-LED and DLP printer

Create highly detailed objects with good surface quality, high precession and excellent accuracy with this good-value resin for your UV-LED or DLP printer. The high-quality Monocure Rapid 3D resin is designed and optimized for 3D printing with LED UV and DLP printers. Thanks to its wide polymerization range from 225 to 420 nanometers, it can be processed on a variety of UV LED and DLP printers.

Material properties of Monocure Rapid Resin:

- Use it with your UV LED & DLP printer

- It can be used with many different brands and devices as the UV technology is very similar.

- High polymerization speed (curing speed)

- Wide range of colours

- Optimized for high-resolution and precise components

- Low material shrinkage of 0.5%.

- Shore hardness D 70

- Negligible odor compared to other resins/resins

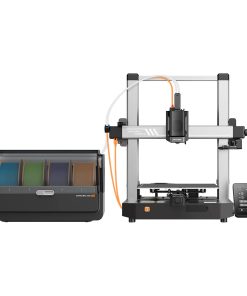

These 3D printers allow you to process Monocure Rapid 3D Resin – for example on your Anycubic Photon, Wanhao D7 & D8, Creality LD-001 and other DLP-3D printers

For example, you can process this resin with your Wanhao Duplicator D7 or Duplicator 8, Anycubic Photon and Creality LD-001. Since almost all UV LED or DLP 3D printers use similar 3D printing technology, you can also use and process this resin on other 3D printers from different manufacturers.

These are possible areas of application for Monocure 3D Rapid Resin:

- Research and development

- Prototyping and prototype construction for research and development

- Components for mechanical engineering and industrial usage

- Medicine models & applications

- Models for architecture & design

- You can also use Monocure 3D Rapid Resin for other applications as well

Wide range of polymerization and reaction ranges – 225 nm to 420 nm wavelength

Monocure Rapid 3D resin is characterized by its wide range of polymerization range and wide reactivity spectrum. This inexpensive and high-quality resin cures at UV wavelengths of 225 to 420 nm. The UV light triggers the photopolymerization process, which then starts. During this chemical reaction, the liquid resin becomes solid and hard due to the energy input of UV light.

Photoinitiators, monomers and sensitizers for a fast polymerization process by UV light in a wide spectrum

By combining a mixture of photoinitiators, monomers and sensitizers, virtually any UV light source can initiate the polymerization process of Monocure Rapid 3D resin. If you wish, you can paint the 3D-printed parts after you have cured them, for example by placing them in a UV post-curing chamber or in sunlight. After complete curing, you can further process Monocure 3D Rapid Resin components and paint them, for example. The applied paint keeps your object protected from sunlight. This ensures that a component made of Monocure 3D Rapid Resin additively remains stable and durable for a longer period of time.

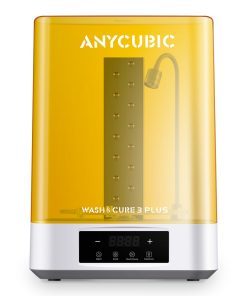

Tips for Cleaning Monocure Rapid 3D Resin – Use Isopropanol and a UV Curing Chamber

After 3D printing, clean the objects with your UV LE or DLP printer by placing them in an isopropanol bath for about 10 minutes. This washes off liquid, unpolymerized material from the component. This allows you to improve surface quality and reveal fine details cleanly. After cleaning, let the parts dry and then place them in a UV curing chamber to cure your resin 3D prints.

Other resin properties:

- Monocure Rapid 3D resin has been tested with a “Shore D hardness durometer” and has a value of 70 (for comparison a safety helmet has a hardness of 80).

- The viscosity of this resin is 500-600 cps at 25 ° C (with Brookfield RVT)

- All our resins are odorless, have no VOC emissions and show very low material shrinkage properties <0.5%>

- We recommend that you store your Monocure 3D Rapid Resin in a dark, cool place without direct sunlight

- If you like to work with a high quality resin on your UV LED or DLP printer, you should buy the Monocure Rapid 3D resin

Buy the Monocure Rapid 3D resin and you’ll get high quality resin for your UV LED and DLP printers.

| Colour | Black, Blue, Clear, Grey, Gunmetal Grey, White |

|---|

Fast Delivery and professional packaging

Our long-standing relationships with UPS FedEx DHL and other international carriers lets us offer various shipping options. Our warehouse personnel are well trained and will be able to pack the goods according to the exact and precise specifications. The goods you send us are checked thoroughly and securely secured prior to shipment. Everyday we deliver thousands of packages to customers across many countries. The fact that we're committed to becoming the biggest online retailer in the World is clear. The warehouses and centers of distribution are in Europe and the USA.

It is important to note that orders with more than one item will be subject to a processing period that is based to the specific item.

Prior to shipping Our team will conduct an extensive inspection of the items you purchased. The majority of orders today are shipped in 48 hours. The delivery time is between 3-7 days.

Returns

Due to multiple entities which include the factory as well as the warehouse, we're unable to completely manage our stock. Stock levels can fluctuate at any given time. It is possible that inventory could run out once your order has been processed.

Our policy is valid for 30 days. We are unable to return or exchange your purchase when it's been 30 days since you purchased it.

The item you purchase must be in its original packaging and be unused. The item must be in its original packaging.

Related products

3D Printer Parts & Spares

3D Printers

3D Printer Parts & Spares

7ml Super Lube Multi-Use Synthetic Oil with Syncolon (PTFE) SuperLube

3D scanners

3D Printer Parts & Spares

3D Printer Parts & Spares

3D Printers

3D Printers

3D Printers

3D Printer Parts & Spares

3D scanners

3D Printer Parts & Spares

3D Printers

3D Printer Parts & Spares

3D Printer Parts & Spares

3D Printer Parts & Spares

85g Super Lube Multi-Purpose Synthetic Grease with Syncolon (PTFE) SuperLube

3D Printer Parts & Spares

3D Printer Parts & Spares

3D Printers

3D Printer Parts & Spares

3D scanners

3D Printers

3D Printer Parts & Spares

3D Printers

3D Printer Parts & Spares