Micro Swiss FlowTech™ Hotend for Creality CR-10 SE Micro Swiss

$ 64,90 $ 32,45

FlowTech™ Hotend for Creality CR-10 SE

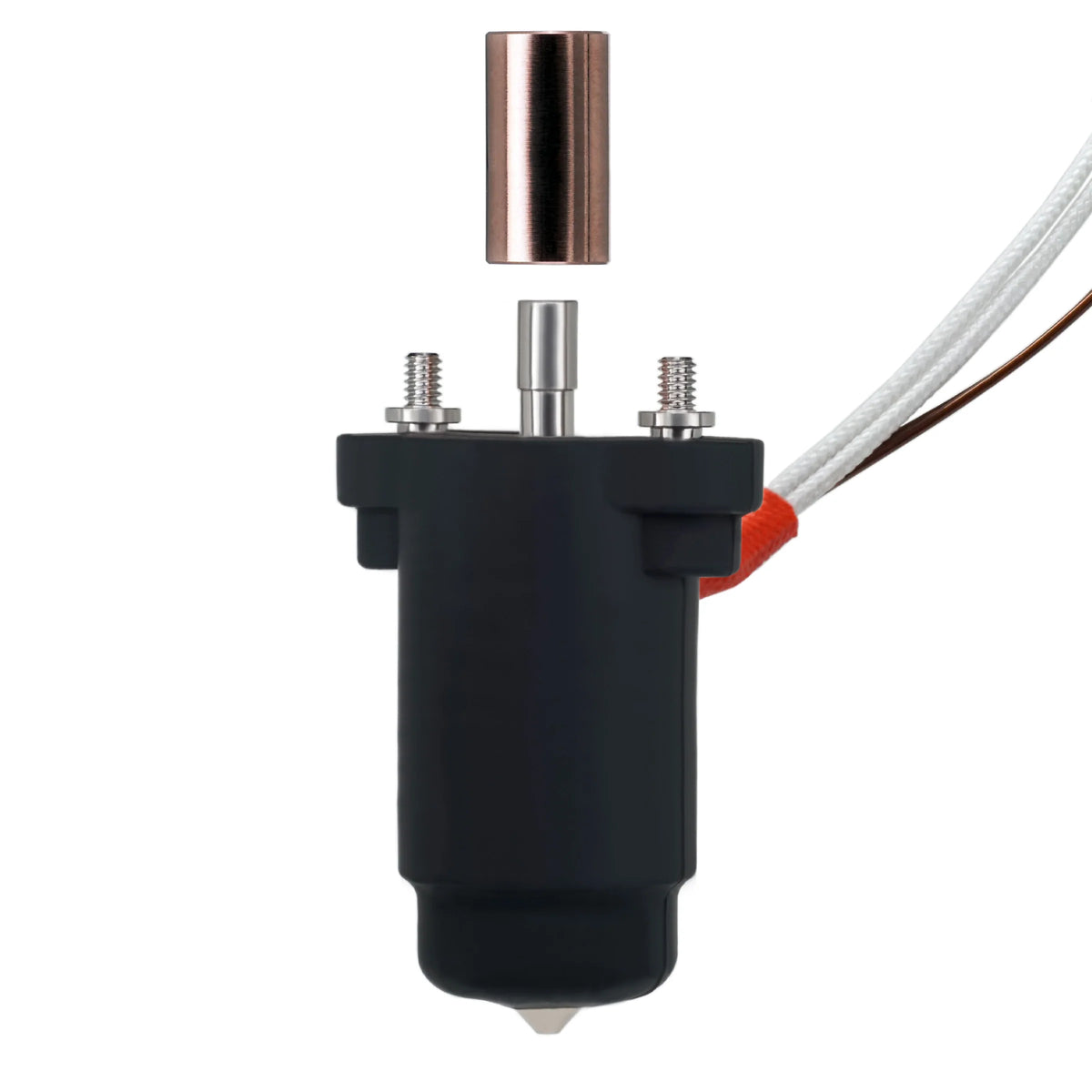

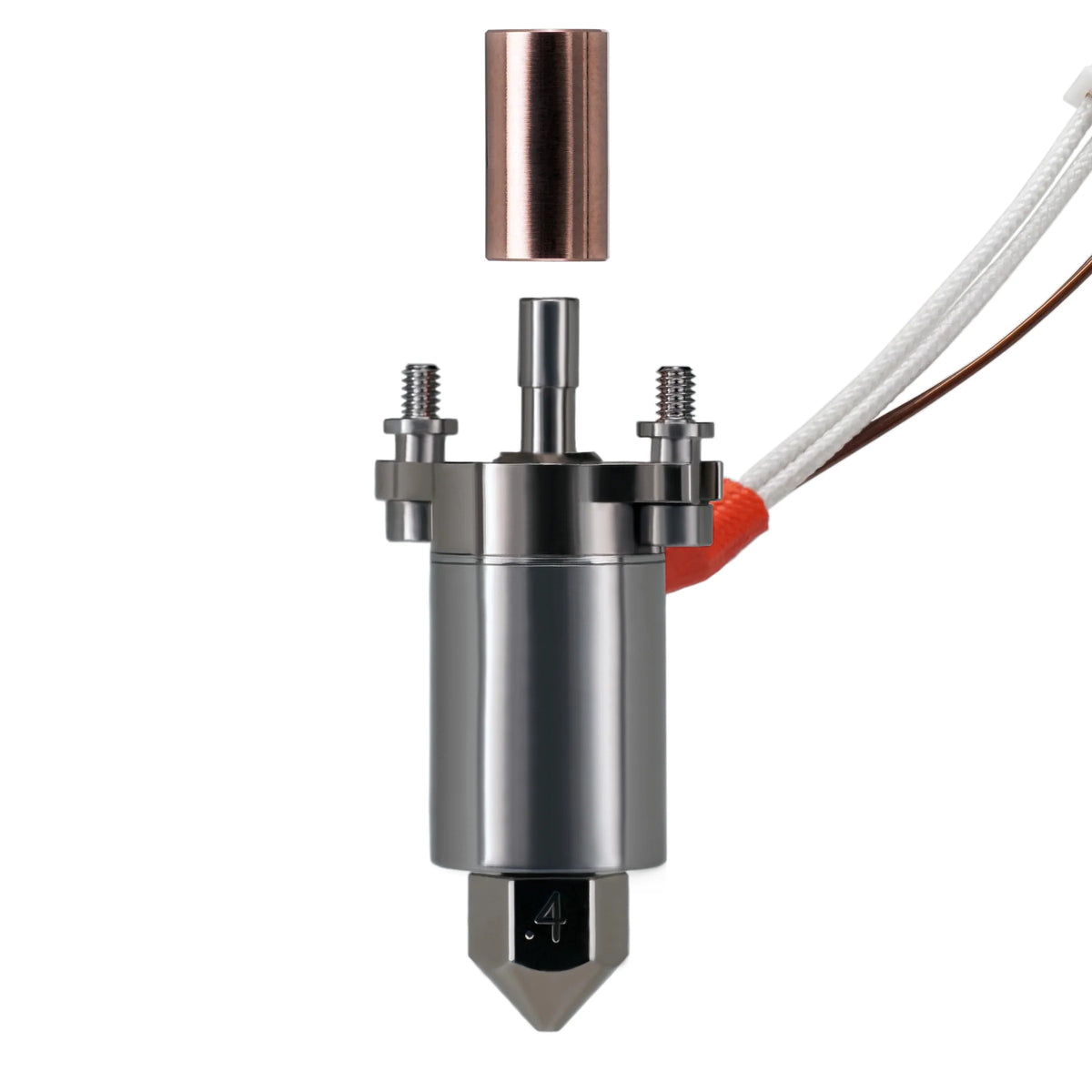

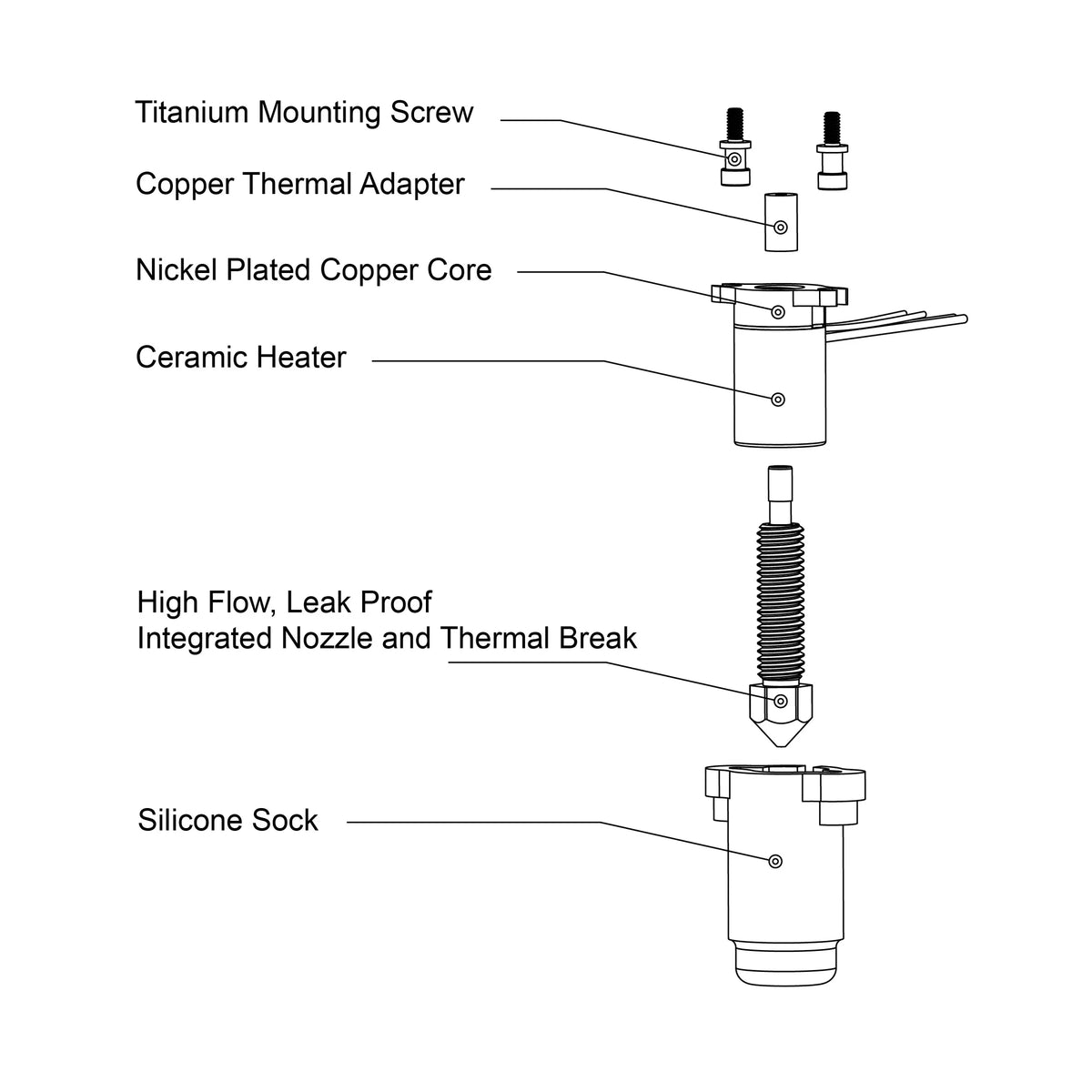

The FlowTech™ Hotend is a new generation hotend line from Micro Swiss. Its unique design eliminates common hotend issues such as leaking nozzle seal and complex nozzle swaps.

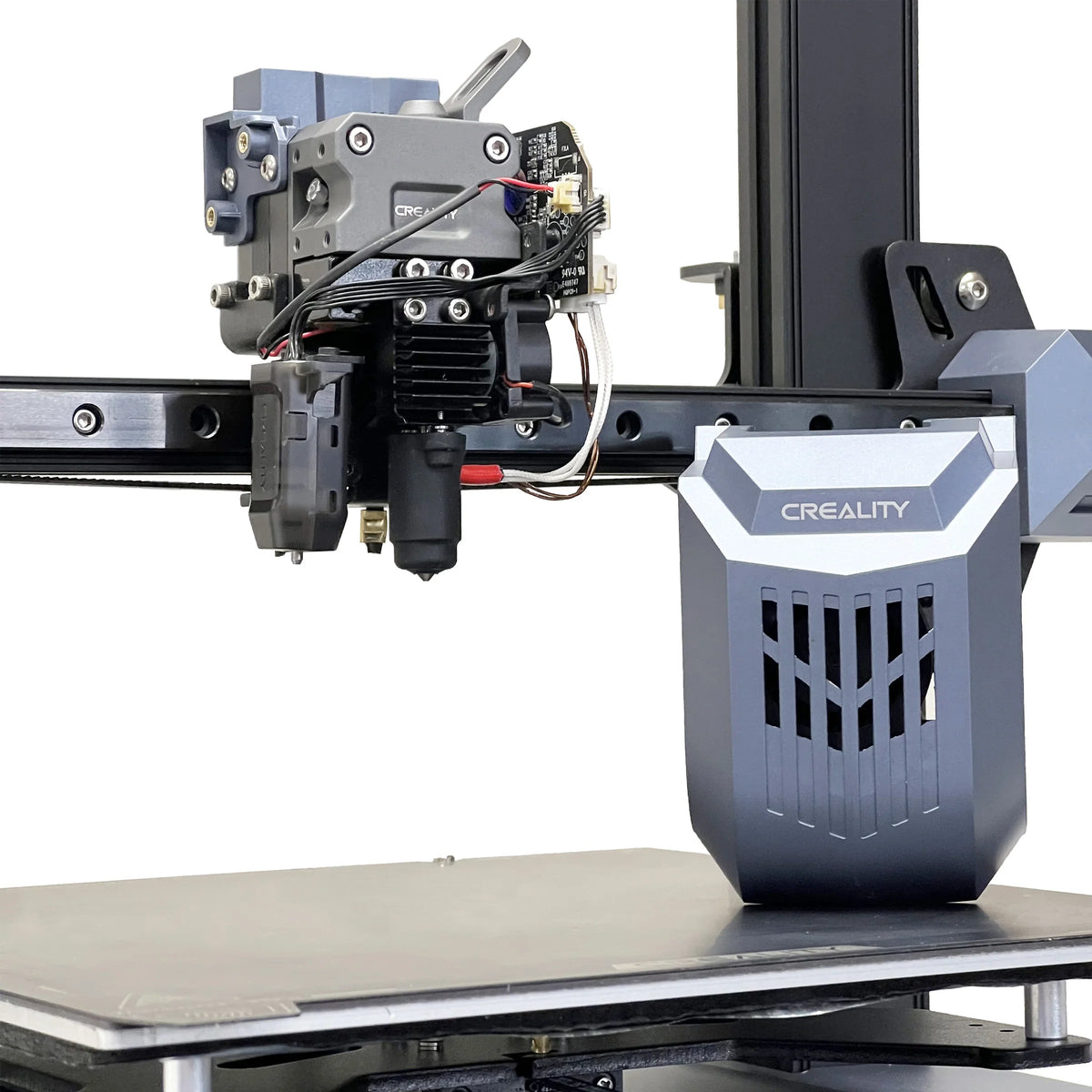

Keeping with our philosophy, the FlowTech hotend is designed to be an easy drop-in upgrade for each 3D printer model. This edition is designed for CR-10 SE. Stock z-height, build volume and firmware remains unchanged.

Features:

-

Leak-Proof Nozzle:

Tired of messy nozzle leaks that ruin your prints and waste filament? FlowTech Hotend combines nozzle and thermal break into one permanently sealed assembly that ensures a leak-proof hotend.BUY NOZZLES

-

Cold Nozzle Change:

Swapping out nozzles used to be a time-consuming and potentially hazardous task. With a FlowTech Hotend, nozzle changes are effortless, and there’s no need for hot tightening, and you can do it with just one hand. -

High-Flow Characteristics:

Ceramic cylindrical heater and 28.6mm melt zone provides excellent volumetric flow rate. -

All-Metal Design:

Built to last! FlowTech hotend features an all-metal design that can handle most modern 3D printing filaments. The entire hotend is machined and assembled in-house, with quality control performed at multiple stages during the manufacturing process. At the end, each hotend undergoes a full thermal cycling test before it is packaged. -

300°C Max Temperature:

This hotend is rated at 300°C temperature with a properly tuned NTC thermistor for each specific printer. This particular edition is perfectly tuned for CR-10 SE so no firmware changes are needed.

Made in USA by Micro Swiss

Fast Delivery and professional packaging

Our long-standing relationships with UPS FedEx DHL and other international carriers lets us offer various shipping options. Our warehouse personnel are well trained and will be able to pack the goods according to the exact and precise specifications. The goods you send us are checked thoroughly and securely secured prior to shipment. Everyday we deliver thousands of packages to customers across many countries. The fact that we're committed to becoming the biggest online retailer in the World is clear. The warehouses and centers of distribution are in Europe and the USA.

It is important to note that orders with more than one item will be subject to a processing period that is based to the specific item.

Prior to shipping Our team will conduct an extensive inspection of the items you purchased. The majority of orders today are shipped in 48 hours. The delivery time is between 3-7 days.

Returns

Due to multiple entities which include the factory as well as the warehouse, we're unable to completely manage our stock. Stock levels can fluctuate at any given time. It is possible that inventory could run out once your order has been processed.

Our policy is valid for 30 days. We are unable to return or exchange your purchase when it's been 30 days since you purchased it.

The item you purchase must be in its original packaging and be unused. The item must be in its original packaging.

Related products

3D Printer Parts & Spares

3D Printer Parts & Spares

3D Printer Parts & Spares

3D Printer Parts & Spares

Bambu Lab Hotend Only for X1 and P1 Series Hardened Steel 0.4mm Bambu Lab

3D Printer Parts & Spares

3D Printer Parts & Spares

3D Printer Parts & Spares

Bambu Lab Hardened Steel Hotend for A1 Series 0.6mm Bambu Lab

3D Printer Parts & Spares

Bambu Lab Stainless Steel Hotend for A1 Series 0.2mm Bambu Lab

3D Printer Parts & Spares

Bambu Lab Complete Hotend Assembly for X1 Series Hardened Steel 0.8mm Bambu Lab

3D Printer Parts & Spares

3D Printer Parts & Spares

Bambu Lab Complete Hotend Assembly for P1 Series Hardened Steel 0.4mm Bambu Lab

3D Printer Parts & Spares

Bambu Lab Hardened Steel Hotend for A1 Series 0.4mm Bambu Lab

3D Printer Parts & Spares

7ml Super Lube Multi-Use Synthetic Oil with Syncolon (PTFE) SuperLube

3D Printer Parts & Spares

Bambu Lab Complete Hotend Assembly for P1 Series Hardened Steel 0.8mm Bambu Lab

3D Printer Parts & Spares

Bambu Lab Hotend Only for X1 and P1 Series Stainless Steel 0.2mm Bambu Lab

3D Printer Parts & Spares

3D Printer Parts & Spares

3D Printer Parts & Spares

3D Printer Parts & Spares

Bambu Lab Complete Hotend Assembly for X1 Series Stainless Steel 0.4mm Bambu Lab

3D Printer Parts & Spares

Bambu Lab Complete Hotend Assembly for P1 Series Stainless Steel 0.2mm Bambu Lab

3D Printer Parts & Spares

3D Printer Parts & Spares

Bambu Lab Hardened Steel Hotend for A1 Series 0.8mm Bambu Lab

3D Printer Parts & Spares

3D Printer Parts & Spares

3D Printer Parts & Spares

3D Printer Parts & Spares

3D Printer Parts & Spares

3D Printer Parts & Spares

3D Printer Parts & Spares

3D Printer Parts & Spares

3D Printer Parts & Spares

3D Printer Parts & Spares