Magigoo Pro PP – GF – The 3D Printing Adhesive Magigoo

$ 30,95 $ 18,57

WHAT: Magigoo PP-GF is designed to work exclusively with glass re-insforced polypropylene(GFPP) filaments.This adhesive makes sure prints stick firmly when the print-bed is hot and that the part is easy to remove once it cools.

WHY:

Polypropylene (PP) is a thermoplastic semi-crystalline polymer exhibiting properties of good strength, impact resistance and ductility making it useful as an engineering material. PP however is a soft material and like most plastics it can be strengthened by the introduction of fibres to make a polymer composite material. These materials are usually stiffer and stronger than the parent polymer and can result in a material with a very high strength to weight ratio. Compared to most virgin PP filaments the GF30PP warps to a higher extent. This type of material requires a completely new adhesive formulation to play to its distinctive characters. .

HOW:

Magigoo PP-GF has been designed and tested to work with 30% glass fiber filled Polypropylene

- Shake the bottle vigorously.

- Apply to the desired area by pressing the nib on the bed (activating the inner valve) and spreading as needed.

- Print according to the filament/printer manufacturers recommendations.

- Allow to cool and Remove. The print should pop right off

- Clean – Use a damp cloth to wipe off.

SAFETY:

Follow Safety Data Sheet warnings

Tips:

- For challenging prints a 20 mm brim with 2 layers is recommended.

- Clean the build plate and level it well before print.

- Enclosed printer recommended.

- Printing speed 20-55mm.

Fast Delivery and professional packaging

Our long-standing relationships with UPS FedEx DHL and other international carriers lets us offer various shipping options. Our warehouse personnel are well trained and will be able to pack the goods according to the exact and precise specifications. The goods you send us are checked thoroughly and securely secured prior to shipment. Everyday we deliver thousands of packages to customers across many countries. The fact that we're committed to becoming the biggest online retailer in the World is clear. The warehouses and centers of distribution are in Europe and the USA.

It is important to note that orders with more than one item will be subject to a processing period that is based to the specific item.

Prior to shipping Our team will conduct an extensive inspection of the items you purchased. The majority of orders today are shipped in 48 hours. The delivery time is between 3-7 days.

Returns

Due to multiple entities which include the factory as well as the warehouse, we're unable to completely manage our stock. Stock levels can fluctuate at any given time. It is possible that inventory could run out once your order has been processed.

Our policy is valid for 30 days. We are unable to return or exchange your purchase when it's been 30 days since you purchased it.

The item you purchase must be in its original packaging and be unused. The item must be in its original packaging.

Related products

Bed Adhesive

3D Printer Parts & Spares

85g Super Lube Multi-Purpose Synthetic Grease with Syncolon (PTFE) SuperLube

Bed Adhesive

3D Printer Parts & Spares

12g Super Lube Multi-Purpose Synthetic Grease with Syncolon (PTFE) SuperLube

Bed Adhesive

3D Printers

3D scanners

3D Printer Parts & Spares

3D Printer Parts & Spares

3D Printers

3D Printers

Bed Adhesive

3D Printers

3D Printers

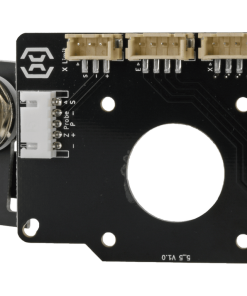

3D Printer Parts & Spares

7ml Super Lube Multi-Use Synthetic Oil with Syncolon (PTFE) SuperLube

Bed Adhesive

3D Printers

3D Printers

3D Printer Parts & Spares

3D scanners

3D scanners

3D Printers

3D Printer Parts & Spares

Bed Adhesive

Bed Adhesive