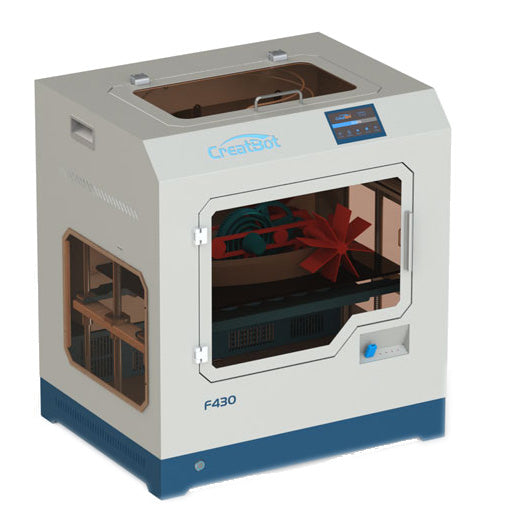

CreatBot F430 – 420°C Version CreatBot

$ 3.980,00 $ 995,00

Support 420°C Hotend

We are the first one to publish 420°C high temperature nozzle to 3d printer market since year of 2016, now it is the 4th new tech version.

F430 equiped with dual extruders, The left 260°C hotend is able to print with PLA, ABS, PC, Nylon, Carbon fiber, Flexible, etc. The right 420°C hotend is made of martensite steel, which is able to print High performance material like PEEK, ULTEM, etc.

The dual hotend is replaceable, which provide more possibility on your application.

To Prolong the life of the glass build plate, we suggest you purchase THIS

![]() 420 ℃ Hotend

420 ℃ Hotend

![]() Direct Drive

Direct Drive

High Precision & High Speed

We exclusively research and develop the extruder feeding system and guide rail, which support high-speed printing. Its printing accuracy can reach high to 0.04mm,and it allows to extrude filament steady without block.

![]() High Precision

High Precision

Precision up to: 0.04 mm

Speed up to: 120 mm/s

Stability

The whole-steel body not only ensure the stability when printing, but also extend the usage period greatly. Its optimization and cooperation of overall structure ensure the sustainable and efficient operation. The first batch of CreatBot 3D printers have been working for 9 years and more than 30,000 hours.

![]() Metal Chassis

Metal Chassis

Fully Enclosed+Hot Chamber 70°C

-Fully enclosed chamber can block all external interfernce and reduce noise.

-Hot chamber device provide constant room temperature 70°C,which is able to prevent prints from warping and deform.

![]() Fully Enclosed

Fully Enclosed

![]() Hot Air System

Hot Air System

Outage Restored & Filament Detection

The printer will automatically memorize the current position and save print data.

Lower the platform and withdraw filament when power off suddenly. It will continue to print from the last stopped point after power’s on.

The printer will avoid invalid printing by stoping print and warning when filament runs out.

![]() Outage Restored

Outage Restored

![]() Filament Detection

Filament Detection

Touch Screen

-The printer have all-english-menu touch screen which is easy – -Operate and friendly use. One key to warm,one key to print as well as many other shortcut keys.

![]() Touch Screen

Touch Screen

Platform

Glass-Ceramic Platform + Carbon Fiber Sheet

The printer has a heatable glass-ceramic platform and a carbon fiber sheet coverd.

Glass-ceramic have hight thermal efficiency and best low-expansion coefficient, so it don’t deform when heating&cooling.

-Carbon fiber sheet is tough and removable. Heat can be deliver efficiently. Most materials can be extruded and sticked to bed very well.

Air Filter System

The air filter system can adsorb impurities and gases that generated by printing special filament, more safe and environmental protection which is more suitable for house, school, office space.

![]() Air Filter System

Air Filter System

Automatic Leveling Platform

BLtouch smart version use of 25 points, use of 25 points through the probe to save the level of platform flatness data at the initial, through the Z axis intelligent compensation table height in the printing process to achieve fully automatic leveling.

Technical Specs

| Printing | |

| Print Technology | Fused Deposition Modeling(FDM) |

| Build Volume | 400*300*300 mm |

| Number of Nozzles | Double |

| Resolution | 0.04 mm |

| Layer Resolution | 0.02 mm |

| Filament Diameter | 1.75 mm |

| Filament Compatibility | PLA, ABS, Carbon Fiber, Wood, Nylon, PC, PTEG, HIPS, PP, Flexible, TPU, PVA, PEEK, etc. |

| Nozzle Diameter | 0.4mm (0.3 0.5 0.6 0.8 1.0mm) |

| Print File Type | STL, OBJ, AMF, Gcode |

| Speed | |

| Best Printing speed | 55 mm/s |

| Max. Printing speed | 180 mm/s |

| Electrical | |

| Power Requirements | 100V-110V or 200V-240V / 50-60Hz (Depending on your country’s default voltage) |

| Max. Power | 1500W |

| Screen | 4.3” Touch Screen |

| Control Chip | ATmega 2560 |

| Storage Media | U Disk |

| Connectivity | USB |

| Special Function | |

| Outage Restored | Save data when power is off |

| Filament Detection | Pause printing when filament run out |

| Automatic Shut-down | Turn off the power automatically when printing is complete |

| Temperature | |

| Ambient Operating Temperature | 15 ℃~32 ℃ |

| Max. Nozzle Temperature | 420 ℃ |

| Max. Bed Temperature | 140 ℃ |

| Max. Chamber Temperature | 70 ℃ |

| Mechanical | |

| Construction | Power-Coated Steel, Aluminum Casting for Motion Components |

| Build Plate | Glass Ceramic Panel |

| Build Plate Leveling | Automatic |

| Extruder | Directly Drive |

| Stepper Motors | 1.8° Step Angle with 1/16 Micro-stepping |

| X Y Positioning Precision | 12.7 μm |

| Z Positioning Precision | 1.25 μm |

| Software | |

| Software Bundle | CreatWare, Simplify 3D, Cura, Slice 3r, etc |

| Supported File Types | STL,OBJ,AMF |

| Operating Systems | Win7/8/10, MacOS |

| Size & Weight | |

| Product Dimensions & Weight | 620*485*680 mm 48 kg |

| Packing Size & Weight | 750*580*720 mm 62 kg |

Fast Delivery and professional packaging

Our long-standing relationships with UPS FedEx DHL and other international carriers lets us offer various shipping options. Our warehouse personnel are well trained and will be able to pack the goods according to the exact and precise specifications. The goods you send us are checked thoroughly and securely secured prior to shipment. Everyday we deliver thousands of packages to customers across many countries. The fact that we're committed to becoming the biggest online retailer in the World is clear. The warehouses and centers of distribution are in Europe and the USA.

It is important to note that orders with more than one item will be subject to a processing period that is based to the specific item.

Prior to shipping Our team will conduct an extensive inspection of the items you purchased. The majority of orders today are shipped in 48 hours. The delivery time is between 3-7 days.

Returns

Due to multiple entities which include the factory as well as the warehouse, we're unable to completely manage our stock. Stock levels can fluctuate at any given time. It is possible that inventory could run out once your order has been processed.

Our policy is valid for 30 days. We are unable to return or exchange your purchase when it's been 30 days since you purchased it.

The item you purchase must be in its original packaging and be unused. The item must be in its original packaging.

Related products

3D Printer Parts & Spares

Bambu Lab Complete Hotend Assembly for P1 Series Hardened Steel 0.4mm Bambu Lab

3D Printers

3D scanners

3D Printers

3D Printer Parts & Spares

3D Printer Parts & Spares

3D Printer Parts & Spares

Bambu Lab Complete Hotend Assembly for P1 Series Hardened Steel 0.6mm Bambu Lab

3D Printer Parts & Spares

3D Printers

3D Printer Parts & Spares

3D Printer Parts & Spares

Bambu Lab Complete Hotend Assembly for P1 Series Hardened Steel 0.8mm Bambu Lab

Bed Adhesive

3D Printer Parts & Spares

Bambu Lab Hardened Steel Hotend for A1 Series 0.4mm Bambu Lab

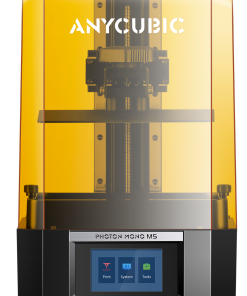

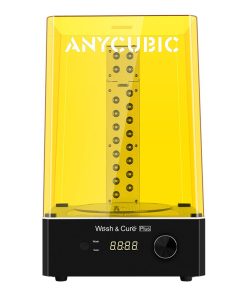

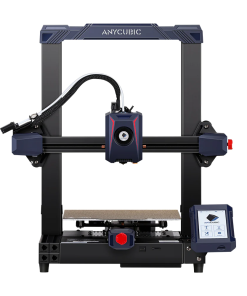

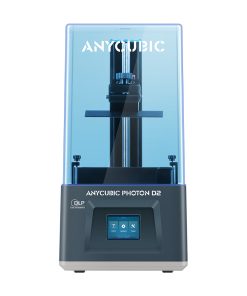

3D Printers

3D Printers

3D Printers

3D Printers

3D Printers

Bed Adhesive

3D Printer Parts & Spares

Bambu Lab Complete Hotend Assembly for X1 Series Hardened Steel 0.6mm Bambu Lab

3D Printer Parts & Spares

Bambu Lab Complete Hotend Assembly for P1 Series Stainless Steel 0.2mm Bambu Lab

3D Printer Parts & Spares

7ml Super Lube Multi-Use Synthetic Oil with Syncolon (PTFE) SuperLube

3D Printer Parts & Spares

Bambu Lab Complete Hotend Assembly for X1 Series Hardened Steel 0.8mm Bambu Lab

3D Printer Parts & Spares

Bambu Lab Complete Hotend Assembly for X1 Series Hardened Steel 0.4mm Bambu Lab

3D Printers

3D Printer Parts & Spares

12g Super Lube Multi-Purpose Synthetic Grease with Syncolon (PTFE) SuperLube

3D Printer Parts & Spares

3D Printer Parts & Spares