Copymaster3D Premium ABS Filament – 1.75mm – 1KG – CLEARANCE Copymaster 3D

$ 10,00 $ 6,00

These sleeves are reusable and only take a small amount of material.

You can find the sleeves for the Copymaster spools on our Thingiverse account via the link below:

https:///thing:5954178/files

Durable and impact resistant

The specific qualities of the filament TechnologyOutlet Smart ABS include a high impact resistance and relatively high rigidity. As compared to the classic ABS filament, the “smart” variant demonstrates improved processing parameters which considerably reduce the difficulties which accompany the additive manufacturing using the standard ABS. It is essentially the lower shrinkage and reduced emission of irritant volatiles during processing. An unquestionable advantage is that the material retains its properties at temperatures down to -40°C.

Key features:

- high impact resistance and rigidity while retaining a relatively high dimensional accuracy

- high gloss of external surface

- reduced warping ratio (0.5-0.7%)

- temperature resistance (HDT 85°C)

- good interlayer adhesion, especially using 3D printer with heated chamber

- low water absorption

- easy processing (grinding, drilling, sawing)

Applications:

- manufacturing of all kinds of enclosures, guards, protectors and other similar items subject to impacts

- possibility of mechanical treatments allows to produce items to facilitate and help conduct installations, i.e. handles, rules, gauges

- end-use parts

- industrial design

- tooling

- custom components

Packaging

Filament is reeled on the neat, transparent spool. Each spool contains information on the type of material, diameter and recommended printing temperature. Filament is vacuum-packed with a moisture absorber.

|

Color: |

Red |

|

RAL: |

3031 |

|

Diameter: |

1.75mm |

|

Dimensional tolerance: |

± 0.05mm |

|

Printing temperature: |

230-255°C |

|

Heated bed: |

needed |

|

Hot pad temperature: |

100°C |

|

Net weight: |

1000g |

|

Total weight: |

1400g |

|

Spool dimensions: |

external diameter – 20cm, internal diameter. 5,2cm, width. 6,7cm |

|

Physical & thermal properties of raw material |

|

|

Specific Gravity: |

1.07 g/cc |

|

Heat Deflection Temperature: |

85°C (ASTM D648) |

|

Vicat Softening Temperature: |

93°C (ASTM D1525) |

|

Flammability – UL94: |

1.5mm – HB class 3.0mm – HB class |

|

Tensile Strength @ Yield: |

45 MPa (ASTM D638) |

| Colour | Bahama Yellow, Forest Green, Lion Orange |

|---|

Fast Delivery and professional packaging

Our long-standing relationships with UPS FedEx DHL and other international carriers lets us offer various shipping options. Our warehouse personnel are well trained and will be able to pack the goods according to the exact and precise specifications. The goods you send us are checked thoroughly and securely secured prior to shipment. Everyday we deliver thousands of packages to customers across many countries. The fact that we're committed to becoming the biggest online retailer in the World is clear. The warehouses and centers of distribution are in Europe and the USA.

It is important to note that orders with more than one item will be subject to a processing period that is based to the specific item.

Prior to shipping Our team will conduct an extensive inspection of the items you purchased. The majority of orders today are shipped in 48 hours. The delivery time is between 3-7 days.

Returns

Due to multiple entities which include the factory as well as the warehouse, we're unable to completely manage our stock. Stock levels can fluctuate at any given time. It is possible that inventory could run out once your order has been processed.

Our policy is valid for 30 days. We are unable to return or exchange your purchase when it's been 30 days since you purchased it.

The item you purchase must be in its original packaging and be unused. The item must be in its original packaging.

Related products

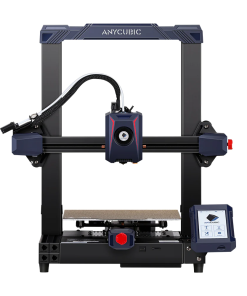

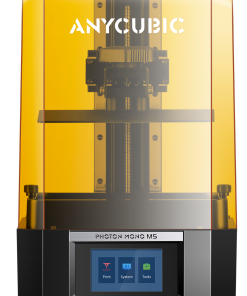

3D Printers

3D Printer Parts & Spares

Bambu Lab Complete Hotend Assembly for X1 Series Hardened Steel 0.8mm Bambu Lab

3D Printers

3D Printer Parts & Spares

85g Super Lube Multi-Purpose Synthetic Grease with Syncolon (PTFE) SuperLube

3D Printer Parts & Spares

3D Printer Parts & Spares

3D Printer Parts & Spares

Bambu Lab Complete Hotend Assembly for X1 Series Hardened Steel 0.6mm Bambu Lab

3D Printers

3D Printers

3D scanners

3D Printer Parts & Spares

Bambu Lab Complete Hotend Assembly for X1 Series Hardened Steel 0.4mm Bambu Lab

3D Printers

3D Printer Parts & Spares

3D Printer Parts & Spares

Bambu Lab Complete Hotend Assembly for P1 Series Hardened Steel 0.4mm Bambu Lab

3D Printers

3D Printers

3D Printers

3D Printer Parts & Spares

3D Printer Parts & Spares

3D Printer Parts & Spares

3D Printer Parts & Spares

7ml Super Lube Multi-Use Synthetic Oil with Syncolon (PTFE) SuperLube

3D Printer Parts & Spares

3D Printers

3D Printer Parts & Spares

Bambu Lab Hardened Steel Hotend for A1 Series 0.6mm Bambu Lab