Raise3D Hyper Speed Upgrade for Pro 3 Series Raise3D

$ 762,00 $ 228,60

HYPER FFF TECHNOLOGY

The Hyper Speed Upgrade Kit is the first product from Raise3D’s Hyper FFF technology. With the upgrade, the printing speed of a Pro3 Series3D printer is boosted from an average of 50-80mm/s to 200-350mm/s, and acceleration is boosted from 1,000 mm/s2 to 10,000 mm/s2, with no loss of accuracy or part quality.

The Kit includes:

- An Upgrade Letter

- Software Upgrades

- Two Hyper Speed Hot Ends 0,4mm (Pro3 Series Only)

- A Hyper Speed Auto Calibrator (Pro3 Series Only)

- A Spool of Hyper Speed PLA Filament White 1 kg / 1.75 mm

- A Spool of Hyper Speed ABS Filament Natural 1 kg / 1.75 mm

HYPER SPEED ABS FILAMENT

Hyper Speed ABS Filament is one of the specially developed filaments from the High-speed filament line for FFF printing. When printing at high speeds, the filament is rapidly fed into the heat block, and the polymer has very little time to melt, from solid to a molten state, which can cause nozzle clogging and poor bonding quality between layers. Additionally, ABS can be subject to warpage and delamination of the printed part during high-speed printing without a heated chamber.

With optimized molecular weight and stiffness, Raise3D Hyper Speed ABS can achieve faster melting and cooling during high-speed printing, which results in lower temperature gradient and inner stress of printed part. With almost no warpage and improved interlayer bonding, Hyper Speed ABS is also perfectly suitable for many functional prototyping parts, tools, and fittings with many different possibilities for post-processing.

Printing settings:

- Nozzle temperature: 210-260 ℃

- Printing Speed: 25-300 mm/s

- Build Platform Temperature: 55-65℃

- Layer Height: 0.1 – 0.2 mm

- Dry Temperature: 50℃

HYPER SPEED PLA FILAMENT

Hyper Speed PLA filament is one of the specially developed filaments from the High-speed filament line for FFF printing. When printing at high speeds, the filament is rapidly fed into the heat block, and the polymer has very little time to melt from solid to a molten state, which can cause nozzle clogging and poor bonding quality between layers. With optimized molecular weight and tuned flowability, Raise3D Hyper Speed PLA can achieve faster melting in the hot end and much quicker cooling after the material has been extruded. As a result, the surface quality of parts printed by Hyper Speed filaments is smooth and most of the sharp details are kept. Most importantly, thanks to optimized molecular weight, Hyper Speed PLA shows excellent interlayer bonding quality and Z-direction strength. Therefore, Hyper speed PLA can be used for concept models and figures, prototyping, etc.

Printing settings:

- Nozzle temperature: 200-230 ℃

- Printing Speed: 50-300 mm/s

- Build Platform Temperature: 45-60℃

- Layer Height: 0.1 – 0.2 mm

- Dry Temperature: 40℃

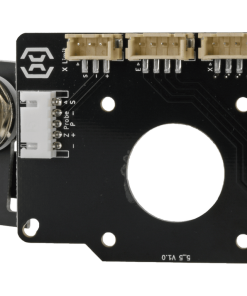

HYPER SPEED AUTO CALIBRATOR

With this auto frequency calibrator, the Pro3 Series printer will be able to measure its own frequency and adjust the parameters by itself. With Pro3 Series’ robust construction and stable design, the printer can keep its own frequency for months without shifting. It is recommended that the calibration process be carried out every 2-3 months. A manual calibration process is also included.

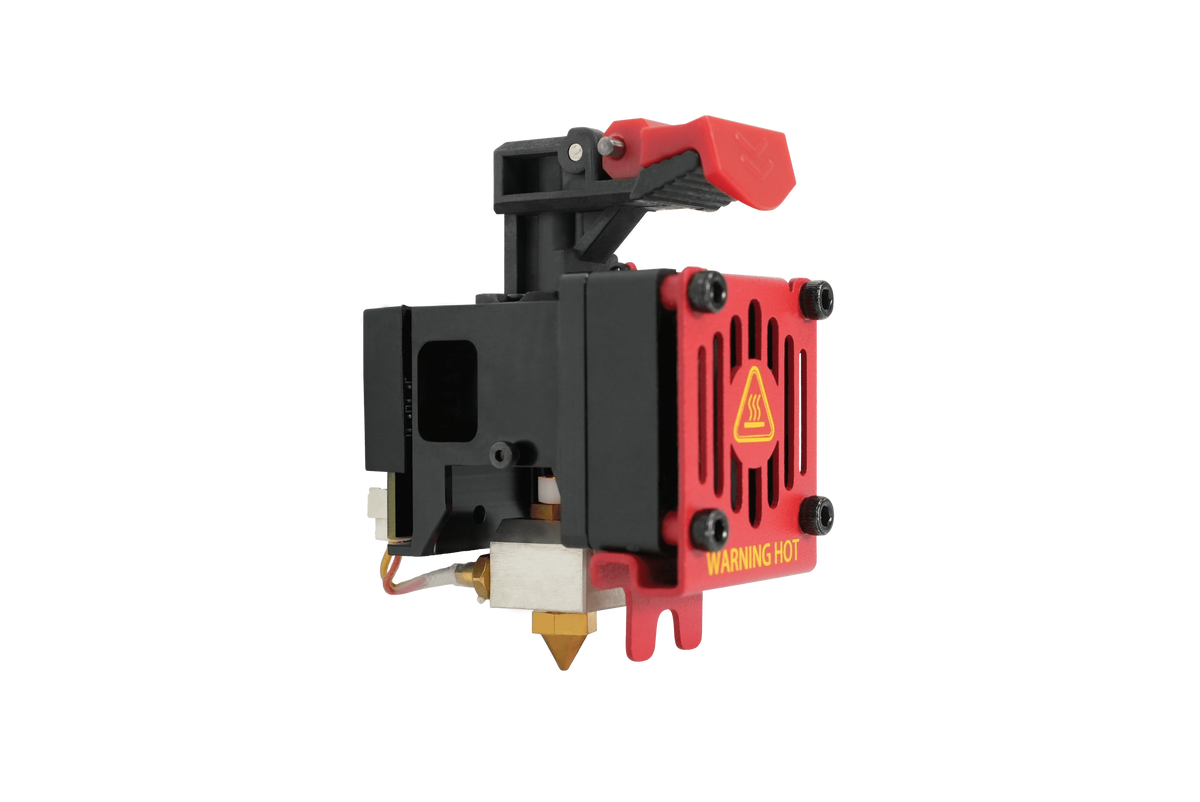

HYPER SPEED HOT END 0.4 MM

High-flowrate hot ends designed for the Pro3 Series on Hyper Speed Mode

Please note that for Hyper Speed to function correctly, the Hyper Speed Hot Ends 0.4mm (Pro3 Series Only), the Hyper Speed Auto Calibrator (Pro3 Series Only), and the Hyper Speed Filaments must be installed on a Pro3 Series printer activated with Hyper Speed Mode. The absence of any of these components may result in printing failure.

Fast Delivery and professional packaging

Our long-standing relationships with UPS FedEx DHL and other international carriers lets us offer various shipping options. Our warehouse personnel are well trained and will be able to pack the goods according to the exact and precise specifications. The goods you send us are checked thoroughly and securely secured prior to shipment. Everyday we deliver thousands of packages to customers across many countries. The fact that we're committed to becoming the biggest online retailer in the World is clear. The warehouses and centers of distribution are in Europe and the USA.

It is important to note that orders with more than one item will be subject to a processing period that is based to the specific item.

Prior to shipping Our team will conduct an extensive inspection of the items you purchased. The majority of orders today are shipped in 48 hours. The delivery time is between 3-7 days.

Returns

Due to multiple entities which include the factory as well as the warehouse, we're unable to completely manage our stock. Stock levels can fluctuate at any given time. It is possible that inventory could run out once your order has been processed.

Our policy is valid for 30 days. We are unable to return or exchange your purchase when it's been 30 days since you purchased it.

The item you purchase must be in its original packaging and be unused. The item must be in its original packaging.

Related products

3D Printers

3D Printers

3D Printer Parts & Spares

3D Printer Parts & Spares

3D Printer Parts & Spares

3D Printer Parts & Spares

3D Printer Parts & Spares

3D scanners

3D Printers

3D Printers

3D Printers

3D Printers

3D Printers

3D Printer Parts & Spares

3D Printers

3D Printer Parts & Spares

3D Printer Parts & Spares

7ml Super Lube Multi-Use Synthetic Oil with Syncolon (PTFE) SuperLube

3D Printer Parts & Spares

3D Printers

3D Printers

3D Printer Parts & Spares

3D scanners

3D Printers

3D Printer Parts & Spares

3D Printer Parts & Spares

3D Printer Parts & Spares

12g Super Lube Multi-Purpose Synthetic Grease with Syncolon (PTFE) SuperLube

3D scanners