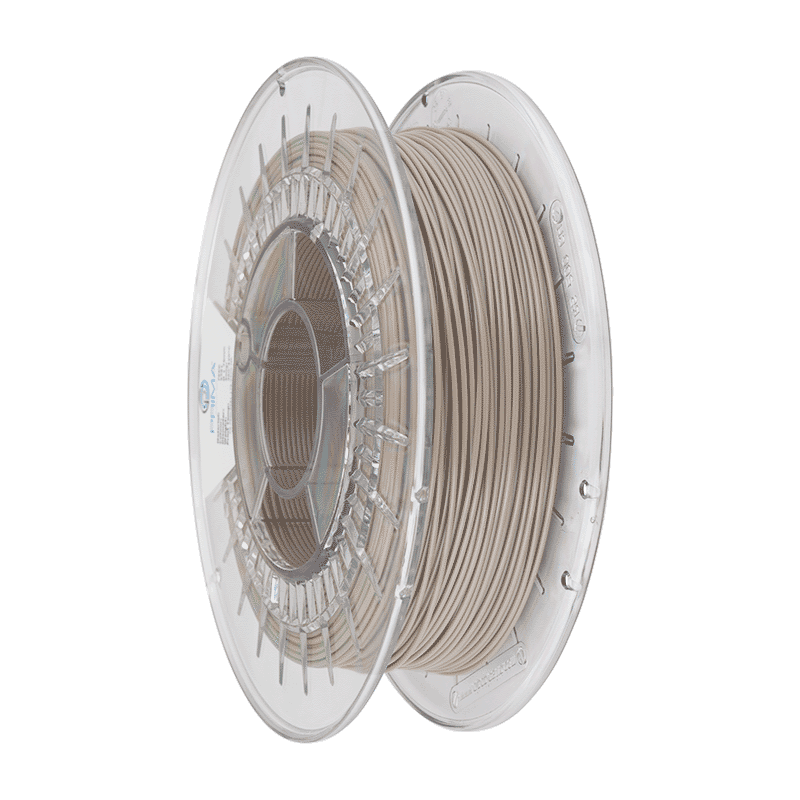

PrimaSelect Luvocom 3F PEKK 50082 – 1.75mm – 500g – Natural PrimaCreator

$ 349,00 $ 104,70

Polyether Ketone Ketone (PEKK) is a semi-crystaline thermoplastic in the Polyaryletherketone family. With high heat resistance, chemical resistance , has the ability to withstand high mechanical loads, is inherent flame retardant and has unique tribological properties.

PEKK Filament has a tuneable crystallization rate which allows FFF or FDM users to take advantage of both the extreme performance of PAEKs and easier processing of amorphous materials; PEKK Filament is easier to print than regular PEEK filament with a better layer adhesion, while offering similar strength and resistance properties; better dimensional stability. PEKK has a higher Tg than PEEK of 15ᵒC.

LUVOCOM® 3F PEKK 50082 is engineered to outperform the standard PEKK materials available in the market. It comes with enhanced flow behaviour which improves the printability and layer adhesion. This unique modified neat PEKK provides dimensional stability and is printable in non-heated chambers, delivering semi-crystalline parts with no warp.

- Specially optimized for industrial 3D printing

- Isotropic shrinkage characteristics

- Non flammable (UL94 V-0)

- Continuous service temperature 255°C

- Service temperature 300°C (during lifetime max. 200h)

- Highly chemically-resistant

- Low warpage

LUVOCOM® 3F PEKK 50082 Material Properties

- Density 1.27 g/cm³

- Tensile Strength 90 MPa

- Elongation at maximum force 5%

- Modulus of elasticity 3 GPa

- Flexural strength 150 MPa

- Flexural elongation at max. force 6%

- Flexural modulus 2,5 GPa

Print Settings

- Print Temperature: 340°C (320-360°C).

- Bed Temperature: 110-140°C

- Print Speed: 20-50 mm/s

- Drying Instruction: 4 hours, 110°C

| Material | PEKK |

| Diameter | 1.75mm |

| Tolerance | ± 0.05 mm |

| Heated build platform required | Yes, 110-140°C |

| Print Temperature | 340 °C (320 – 360 °C |

| Print Speed | 20 – 50 mm/s |

| Drying | 4 hours, 110°C |

| Weight Filament | 0.5 kg |

| Density | 1.27 g/cm³ |

| Tensile Strength | 90 MPa |

| Elongation at maximum force | 5% |

| Modulus of elasticity | 3 GPa |

| Flexural strength | 150 Mpa |

| Flexural elongation at max. force | 6% |

| Flexural modulus | 2.5 GPa |

Fast Delivery and professional packaging

Our long-standing relationships with UPS FedEx DHL and other international carriers lets us offer various shipping options. Our warehouse personnel are well trained and will be able to pack the goods according to the exact and precise specifications. The goods you send us are checked thoroughly and securely secured prior to shipment. Everyday we deliver thousands of packages to customers across many countries. The fact that we're committed to becoming the biggest online retailer in the World is clear. The warehouses and centers of distribution are in Europe and the USA.

It is important to note that orders with more than one item will be subject to a processing period that is based to the specific item.

Prior to shipping Our team will conduct an extensive inspection of the items you purchased. The majority of orders today are shipped in 48 hours. The delivery time is between 3-7 days.

Returns

Due to multiple entities which include the factory as well as the warehouse, we're unable to completely manage our stock. Stock levels can fluctuate at any given time. It is possible that inventory could run out once your order has been processed.

Our policy is valid for 30 days. We are unable to return or exchange your purchase when it's been 30 days since you purchased it.

The item you purchase must be in its original packaging and be unused. The item must be in its original packaging.

Related products

3D Printer Parts & Spares

Bambu Lab Complete Hotend Assembly for X1 Series Hardened Steel 0.6mm Bambu Lab

3D Printer Parts & Spares

3D Printer Parts & Spares

7ml Super Lube Multi-Use Synthetic Oil with Syncolon (PTFE) SuperLube

3D Printer Parts & Spares

3D Printer Parts & Spares

Bambu Lab Hardened Steel Hotend for A1 Series 0.4mm Bambu Lab

3D scanners

3D Printers

3D Printer Parts & Spares

85g Super Lube Multi-Purpose Synthetic Grease with Syncolon (PTFE) SuperLube

3D Printers

3D Printer Parts & Spares

Bambu Lab Hardened Steel Hotend for A1 Series 0.6mm Bambu Lab

3D Printer Parts & Spares

3D scanners

3D Printer Parts & Spares

3D Printer Parts & Spares

Bambu Lab Complete Hotend Assembly for X1 Series Hardened Steel 0.4mm Bambu Lab

3D Printer Parts & Spares

3D Printers

3D Printer Parts & Spares

3D Printer Parts & Spares

3D Printers

3D Printer Parts & Spares

12g Super Lube Multi-Purpose Synthetic Grease with Syncolon (PTFE) SuperLube

3D Printers

3D Printer Parts & Spares

Bambu Lab Complete Hotend Assembly for P1 Series Stainless Steel 0.2mm Bambu Lab

3D Printer Parts & Spares

Bambu Lab Complete Hotend Assembly for P1 Series Hardened Steel 0.8mm Bambu Lab

3D Printer Parts & Spares

3D Printer Parts & Spares

3D Printer Parts & Spares

Bambu Lab Complete Hotend Assembly for P1 Series Hardened Steel 0.6mm Bambu Lab

3D scanners