PrimaCreator MK8 Brass Ruby Nozzle PrimaCreator

$ 51,95 $ 25,98

MK8 Ruby Nozzle 0.4, 0.6 and 0.8mm.

Fits to: Creality MK8 series hotends, MakerBot Replicator 2, CraftBot series.

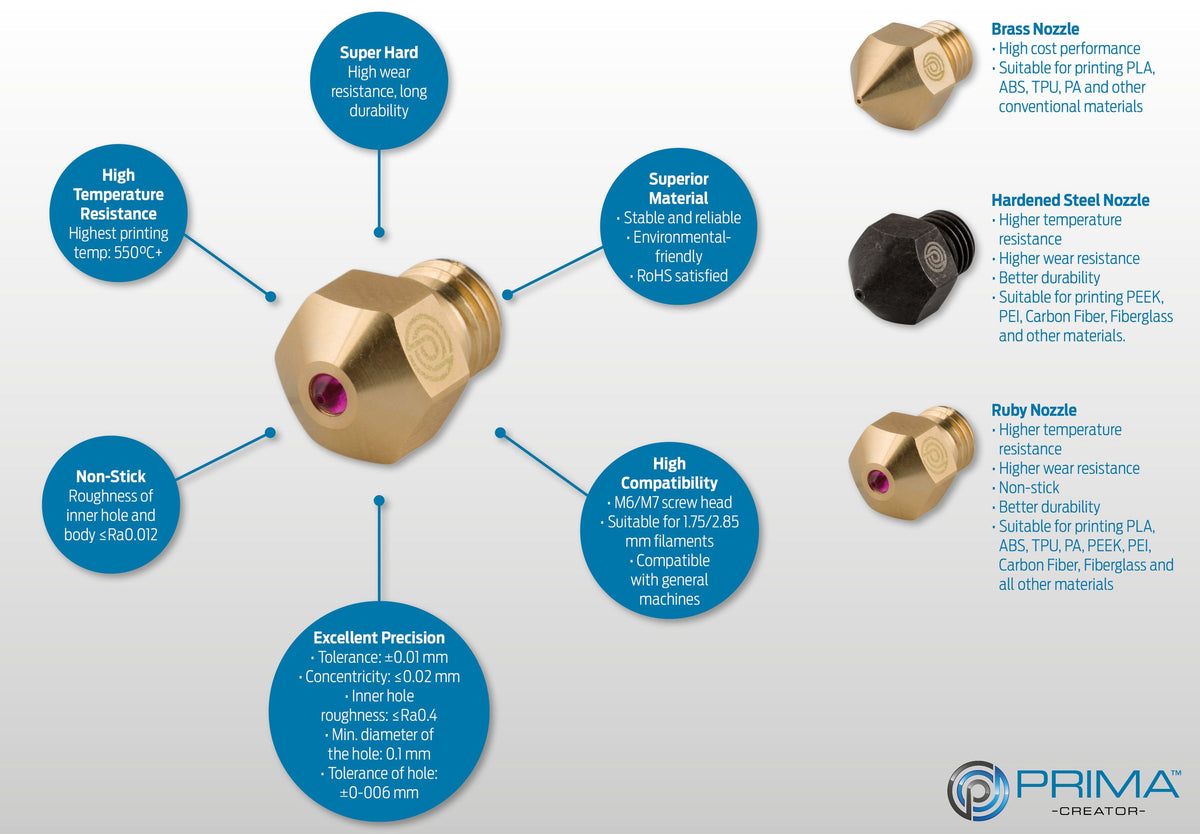

The PrimaCreator Ruby Nozzle is the latest addition to the range of PrimaCreator nozzles.

A regular brass nozzle is most often recommended as they have a superior conductivity when it comes to heat. But a brass nozzle has its draw backs. If you want to print with an abrasive material like carbon or glow in the dark filament a regular brass nozzle will wear out in a very short time. This is why you can choose to use a hardened steel nozzle, it will not wear out as quick as a brass nozzle but it´s made of steel and as a material it´s not optimized for being used as an “every day nozzle” due to the fact that the heat conductivity isn´t as good as in a brass nozzle.

The most logical solution would be to have the best of both worlds.

Enter the PrimaCreator Ruby Nozzle.

In the best nozzle we ever produced we have the same high-quality brass as in our regular nozzles but in addition to this we have also added a small ruby gemstone at the tip of the nozzle. This transforms a regular brass nozzle to a nozzle you can use with your standard filament like PLA, ABS, PETG and so on to the more abrasive ones like carbon filled filament, metal, glow in the dark, wood, well, most types of “nozzle killer filament” you can think about that are currently on the market.

Finally, you can use one nozzle for all your materials.

All ruby nozzles from PrimaCreator are made from the best high-quality brass with a genuine ruby tip. They are completed in a state-of-the-art factory. All nozzles are manufactured with a tolerance of less than ± 0.01 mm. This means that your filament will have a very smooth and clear surface while extruding which, of course, results in better prints.

For best results and optimal print quality, we highly recommend that you re-level your build plate after changing to a new nozzle. Note that a Prima Creator nozzle might be compatible with your printer, but the distance between nozzle and build plate must be adjusted.

The process of making a Prima Creator nozzle begins with a selected high-quality material. When the material reaches the factory, there is first an optical inspection made of the material that are going to be used for each batch of nozzles. Then it´s time to clamp the material, in other words, make it into a long rod. In our process this only is done once, in many other (cheaper) cases, this process must be repeated several times, often as many as 3-4 times and yet you don´t get the same results.

After this process, the material goes through an ultrasonic cleaning bath and after that it is cleaned again and protected against surface oxidation.

The nozzle will now take shape with millimeter precision, the tolerance is less than ± 0.01 mm.

The process of removing sharp edges from the nozzles is a very important step as this makes up a big part of the result. If there is too much sharp edges left on the nozzle it will make the nozzle more prone to clog. So, it´s essential that the nozzle is very smooth and clean before it is used. In every batch a few nozzles are selected and cut in half to make sure that every specification is met, and that the surface is in perfect condition.

The nozzles are then checked for one last time and packed individually in a protective box – ready to be shipped to you.

The ruby nozzle from PrimaCreator is the perfect choice for people who only wants the best and at a great value!

Why should I use a ruby nozzle?

- All filaments, one nozzle

- Extreme durability

- Perfect for very abrasive filaments like carbon, glow in the dark, glass fiber, metal, wood.

- Perfect diameter without jagged edges equals better print quality

| Size | 0.4mm, 0.6mm, 0.8mm |

|---|

Fast Delivery and professional packaging

Our long-standing relationships with UPS FedEx DHL and other international carriers lets us offer various shipping options. Our warehouse personnel are well trained and will be able to pack the goods according to the exact and precise specifications. The goods you send us are checked thoroughly and securely secured prior to shipment. Everyday we deliver thousands of packages to customers across many countries. The fact that we're committed to becoming the biggest online retailer in the World is clear. The warehouses and centers of distribution are in Europe and the USA.

It is important to note that orders with more than one item will be subject to a processing period that is based to the specific item.

Prior to shipping Our team will conduct an extensive inspection of the items you purchased. The majority of orders today are shipped in 48 hours. The delivery time is between 3-7 days.

Returns

Due to multiple entities which include the factory as well as the warehouse, we're unable to completely manage our stock. Stock levels can fluctuate at any given time. It is possible that inventory could run out once your order has been processed.

Our policy is valid for 30 days. We are unable to return or exchange your purchase when it's been 30 days since you purchased it.

The item you purchase must be in its original packaging and be unused. The item must be in its original packaging.

Related products

3D Printer Parts & Spares

3D Printer Parts & Spares

Bambu Lab Complete Hotend Assembly for P1 Series Hardened Steel 0.4mm Bambu Lab

3D Printer Parts & Spares

85g Super Lube Multi-Purpose Synthetic Grease with Syncolon (PTFE) SuperLube

3D Printer Parts & Spares

3D Printer Parts & Spares

Bambu Lab Hotend Only for X1 and P1 Series Stainless Steel 0.4mm Bambu Lab

3D Printer Parts & Spares

Bambu Lab Stainless Steel Hotend for A1 Series 0.2mm Bambu Lab

3D Printer Parts & Spares

3D Printer Parts & Spares

Bambu Lab Hotend Only for X1 and P1 Series Hardened Steel 0.8mm Bambu Lab

3D Printer Parts & Spares

Bambu Lab Hotend Only for X1 and P1 Series Hardened Steel 0.6mm Bambu Lab

3D Printer Parts & Spares

3D Printer Parts & Spares

3D Printer Parts & Spares

Bambu Lab Complete Hotend Assembly for X1 Series Stainless Steel 0.4mm Bambu Lab

3D Printer Parts & Spares

Bambu Lab Hotend Only for X1 and P1 Series Stainless Steel 0.2mm Bambu Lab

3D Printer Parts & Spares

3D Printer Parts & Spares

7ml Super Lube Multi-Use Synthetic Oil with Syncolon (PTFE) SuperLube

3D Printer Parts & Spares

3D Printer Parts & Spares

3D Printer Parts & Spares

Bambu Lab Hardened Steel Hotend for A1 Series 0.6mm Bambu Lab

3D Printer Parts & Spares

3D Printer Parts & Spares

3D Printer Parts & Spares

Bambu Lab Complete Hotend Assembly for X1 Series Hardened Steel 0.8mm Bambu Lab

3D Printer Parts & Spares

3D Printer Parts & Spares

3D Printer Parts & Spares

3D Printer Parts & Spares

Bambu Lab Complete Hotend Assembly for X1 Series Hardened Steel 0.4mm Bambu Lab

3D Printer Parts & Spares

Bambu Lab Complete Hotend Assembly for P1 Series Hardened Steel 0.6mm Bambu Lab

3D Printer Parts & Spares

Bambu Lab Hardened Steel Hotend for A1 Series 0.4mm Bambu Lab

3D Printer Parts & Spares

3D Printer Parts & Spares

Bambu Lab Hotend Only for X1 and P1 Series Hardened Steel 0.4mm Bambu Lab

3D Printer Parts & Spares

3D Printer Parts & Spares

3D Printer Parts & Spares

Bambu Lab Complete Hotend Assembly for P1 Series Hardened Steel 0.8mm Bambu Lab