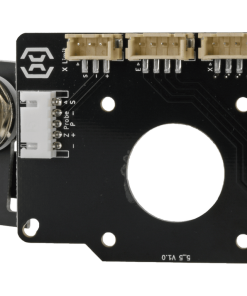

M2559-04 Micro Swiss MK10 All Metal Hotend Kit Micro Swiss

$ 34,96 $ 20,98

STEP BY STEP INSTALLATION INSTRUCTION

This is an all metal hotend upgrade for MK10 style extruders. This upgrade includes a modified thermal barrier tube and modified nozzle. Thermal barrier tube is made from 2 different materials. The lower thermal break is made from stainless steel, and the colder upper part is made from aluminum. Stainless steel was used for thermal break because it offers low thermal conductivity, and aluminum was used for the upper portion because it has a lot better thermal conductivity, to carry away any heat from the filament. All metal hotend will let you print at much higher temperature then possible with original PTFE lined one. Another benefit of an all metal hotend design is more consistent melt chamber control. During slow extrusion rate, in PTFE lined hotend, transition zone from solid to molten plastic tends to creep upward creating more stringy prints. With all metal design a transition zone is always constant, being located right at the heat break. With fast extrusion rate, PTFE tube doesn’t have enough thermal conductivity to properly melt all the plastic coming out. On MK10 extruders that limitation happens around 60 mm/s, depending on nozzle size. All metal hotend solves this problem, plastic is surrounded by thermally conductive nozzle throughout its length.

Kit includes:

- 1 Plated Brass Wear Resistant Nozzle (0.4mm)

- 1 Thermal tube

- 1 Thermal compound

Fits:

- FlashForge Creator Pro

- FlashForge Creator X

- FlashForge Dreamer

- Dremel Idea Builder

- PowerSpec 3D Pro

- PowerSpec 3D X

- Wanhao Duplicator 4S

- Wanhao Duplicator 4X

- Wanhao i3

- Qidi Tech

Fast Delivery and professional packaging

Our long-standing relationships with UPS FedEx DHL and other international carriers lets us offer various shipping options. Our warehouse personnel are well trained and will be able to pack the goods according to the exact and precise specifications. The goods you send us are checked thoroughly and securely secured prior to shipment. Everyday we deliver thousands of packages to customers across many countries. The fact that we're committed to becoming the biggest online retailer in the World is clear. The warehouses and centers of distribution are in Europe and the USA.

It is important to note that orders with more than one item will be subject to a processing period that is based to the specific item.

Prior to shipping Our team will conduct an extensive inspection of the items you purchased. The majority of orders today are shipped in 48 hours. The delivery time is between 3-7 days.

Returns

Due to multiple entities which include the factory as well as the warehouse, we're unable to completely manage our stock. Stock levels can fluctuate at any given time. It is possible that inventory could run out once your order has been processed.

Our policy is valid for 30 days. We are unable to return or exchange your purchase when it's been 30 days since you purchased it.

The item you purchase must be in its original packaging and be unused. The item must be in its original packaging.

Related products

3D Printer Parts & Spares

3D Printer Parts & Spares

3D Printer Parts & Spares

Bambu Lab Complete Hotend Assembly for X1 Series Stainless Steel 0.4mm Bambu Lab

3D Printer Parts & Spares

3D Printer Parts & Spares

Bambu Lab Hotend Only for X1 and P1 Series Hardened Steel 0.4mm Bambu Lab

3D Printer Parts & Spares

Bambu Lab Complete Hotend Assembly for X1 Series Hardened Steel 0.8mm Bambu Lab

3D Printer Parts & Spares

Bambu Lab Hardened Steel Hotend for A1 Series 0.4mm Bambu Lab

3D Printer Parts & Spares

3D Printer Parts & Spares

3D Printer Parts & Spares

Bambu Lab Hotend Only for X1 and P1 Series Hardened Steel 0.6mm Bambu Lab

3D Printer Parts & Spares

Bambu Lab Complete Hotend Assembly for P1 Series Hardened Steel 0.4mm Bambu Lab

3D Printer Parts & Spares

Bambu Lab Complete Hotend Assembly for P1 Series Hardened Steel 0.6mm Bambu Lab

3D Printer Parts & Spares

Bambu Lab Hotend Only for X1 and P1 Series Stainless Steel 0.2mm Bambu Lab

3D Printer Parts & Spares

12g Super Lube Multi-Purpose Synthetic Grease with Syncolon (PTFE) SuperLube

3D Printer Parts & Spares

Bambu Lab Stainless Steel Hotend for A1 Series 0.2mm Bambu Lab

3D Printer Parts & Spares

3D Printer Parts & Spares

3D Printer Parts & Spares

3D Printer Parts & Spares

3D Printer Parts & Spares

3D Printer Parts & Spares

Bambu Lab Complete Hotend Assembly for P1 Series Stainless Steel 0.2mm Bambu Lab

3D Printer Parts & Spares

3D Printer Parts & Spares

3D Printer Parts & Spares

3D Printer Parts & Spares

3D Printer Parts & Spares

3D Printer Parts & Spares

3D Printer Parts & Spares

3D Printer Parts & Spares

85g Super Lube Multi-Purpose Synthetic Grease with Syncolon (PTFE) SuperLube

3D Printer Parts & Spares

3D Printer Parts & Spares

3D Printer Parts & Spares

Bambu Lab Hotend Only for X1 and P1 Series Stainless Steel 0.4mm Bambu Lab